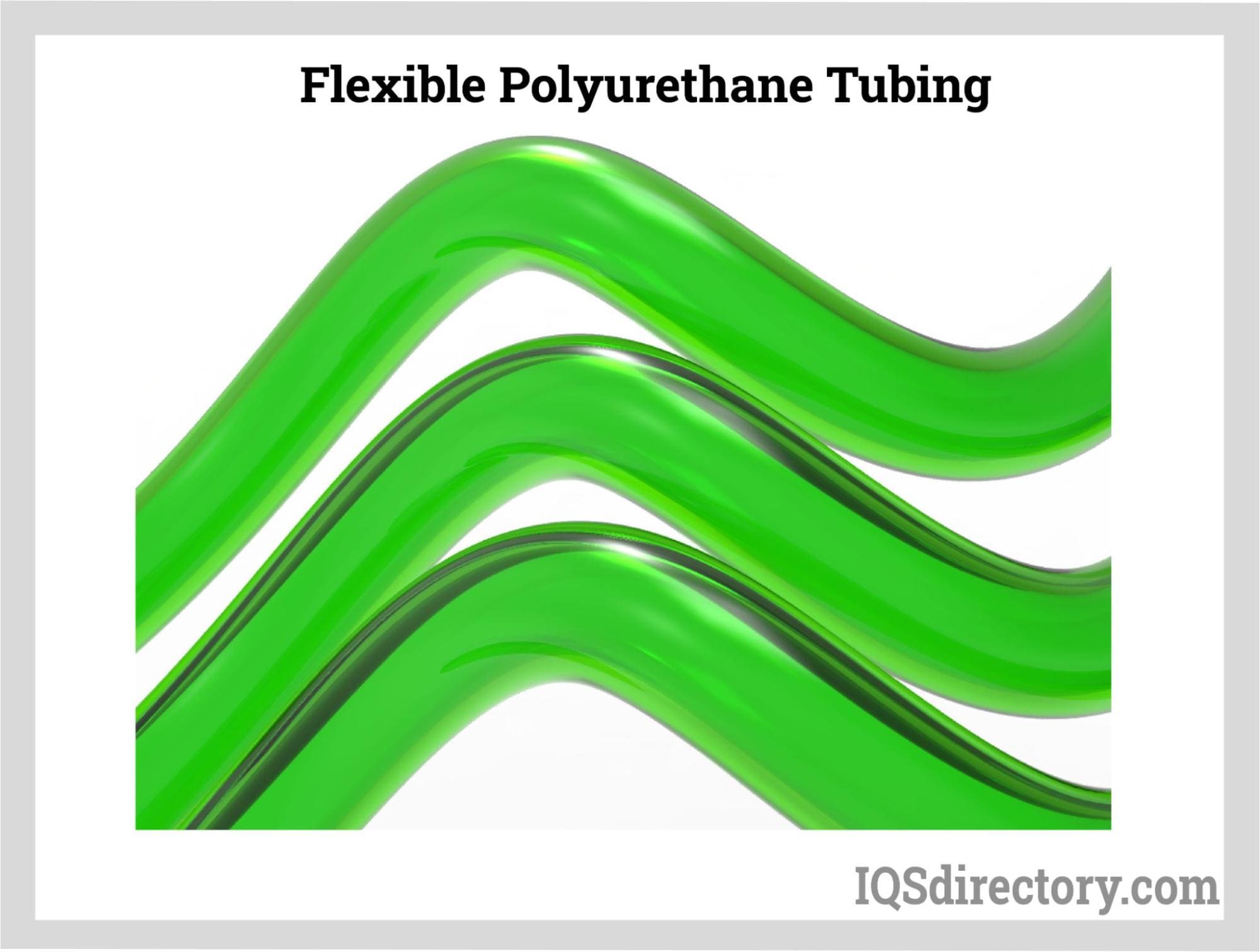

Flexible plastic tubing is a type of tubing made from plastic materials such as polyethylene, PVC, nylon, and polyurethane. The tubing is known for its ability to bend and flex, making it ideal for use in various applications. The earliest plastic tubing was made from polyvinyl chloride (PVC), which was invented in 1926 by a German chemist named Waldo Semon. PVC tubing was initially used for insulation in electrical wiring, but its flexibility and durability soon led to its use in a wide range of applications for various industries. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

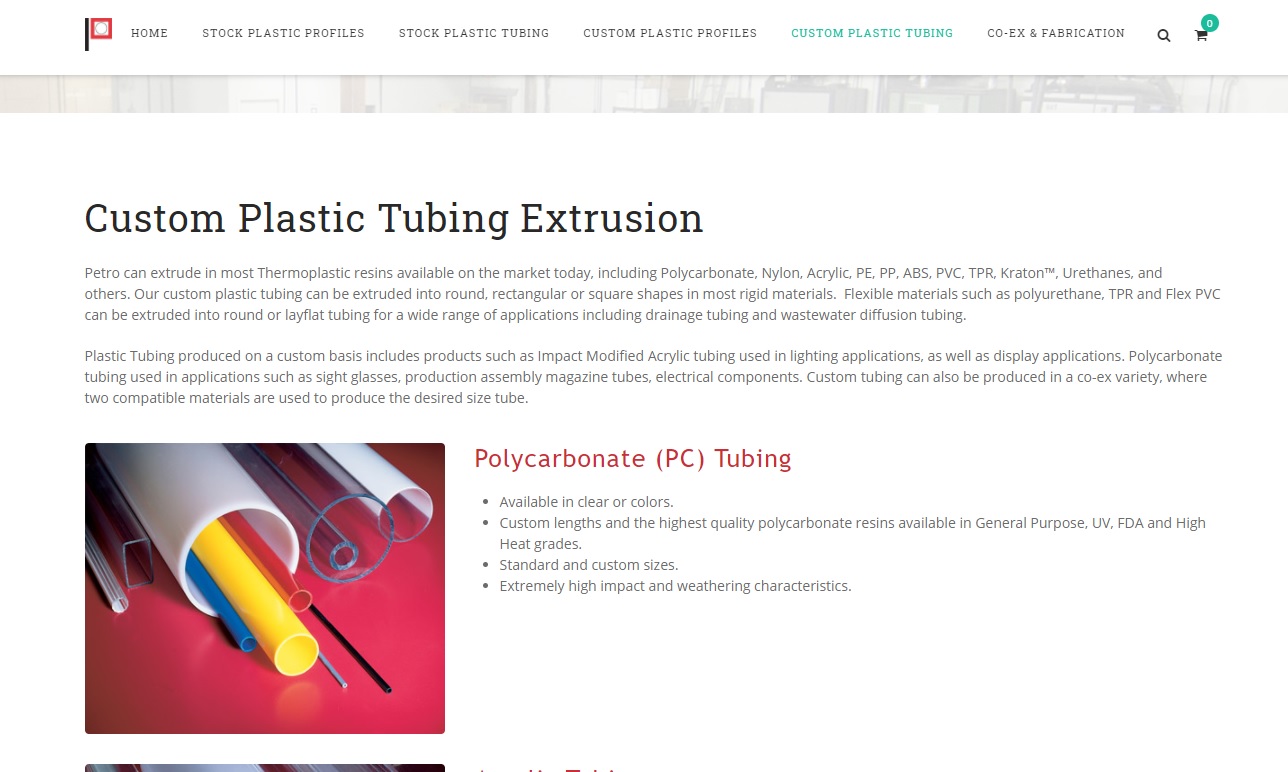

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Flexible Plastic Tubing Manufacturers

How is Flexible Plastic Tubing Made?

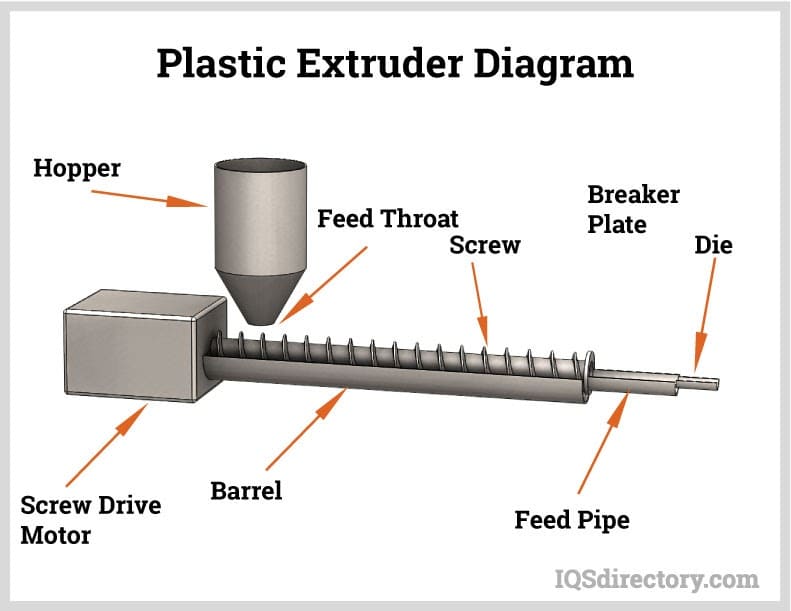

Flexible plastic tubing is typically created using an extrusion process. This process involves heating and melting the plastic material and then forcing it through a die to create the desired shape and size of the tubing. The tubing can then be cut to the desired length and subjected to secondary operations such as printing, marking, and packaging.

How Is One Plastic Chosen?

The type of plastic material used for flexible tubing can vary depending on the intended application. For example, polyethylene tubing is commonly used in the medical industry due to its flexibility and biocompatibility. PVC tubing is used in the automotive and electrical industries due to its resistance to chemicals and moisture.

Limitations of Flexible Plastic Tubing

One of the major limitations of flexible plastic tubing is its impact on the environment. Plastic waste is a significant problem globally, and the disposal of plastic tubing can contribute to this issue. Additionally, flexible tubing has limitations in its pressure and temperature capabilities. The tubing may also be subject to chemical degradation over time.

Benefits of Flexible Plastic Tubing

Despite its limitations, flexible plastic tubing offers several benefits. The tubing is easy to install in tight spaces. It is also lightweight, which reduces transportation costs. Flexible plastic tubing's resistance to corrosion, moisture, and UV radiation makes it ideal for use in harsh environments because it can withstand exposure to elements that can cause damage to other materials. These properties allow the tubing to maintain its integrity and functionality over time, even when exposed to extreme temperatures, moisture, chemicals, and sunlight.

Applications of Flexible Plastic Tubing

Flexible plastic tubing is used in a variety of industries, including:

Medical Equipment: Flexible plastic tubing is often used in medical equipment because it is lightweight, flexible, and can be sterilized easily. It’s used in catheters, IV tubing, and other medical devices that require flexibility and cleanliness.

Automotive Industry: Flexible plastic tubing is used in the automotive industry to transport fluids and gasses in engine and fuel systems. It is preferred over metal tubing because it is lightweight and does not corrode or rust. Additionally, flexible plastic tubing can be easily molded into complex shapes and sizes, making it an ideal choice for custom automotive applications.

Water Filtration Systems: Flexible plastic tubing is commonly used in water filtration systems because it is resistant to chemicals and moisture, making it ideal for use with harsh chemicals and liquids. Additionally, it’s easy to install and maneuver through tight spaces.

Food and Beverage Industry: Flexible plastic tubing is used in the food and beverage industry because it is non-toxic, odorless, and tasteless. It is commonly used to transport liquids, such as milk, juice, and beer, as well as gasses, such as carbon dioxide.

Industrial Machinery: Flexible plastic tubing is used in industrial machinery because it is resistant to chemicals, abrasion, and extreme temperatures. It is commonly used to transport chemicals, gasses, and liquids in industrial applications, such as chemical processing plants and oil refineries.

Agriculture/Irrigation Systems: Flexible plastic tubing is used in agriculture/irrigation systems because it is resistant to weather, chemicals, and UV radiation. It is ideal for transporting water, fertilizers, and pesticides, as it can withstand exposure to harsh environments and chemicals without breaking down or corroding. Additionally, its flexibility allows it to be easily maneuvered around obstacles and through tight spaces, making it an ideal choice for irrigation systems.

Consumer Products and Appliances: Flexible plastic tubing is used in a wide range of consumer products and appliances, including refrigerators, dishwashers, and air conditioners. Its flexibility and durability make it ideal for use in applications where it needs to be bent or twisted to fit into tight spaces. Additionally, its resistance to moisture and chemicals makes it ideal for use in appliances that come into contact with liquids, such as dishwashers and washing machines.

Choosing the Proper Flexible Plastic Tubing Manufacturer

To ensure you have the most satisfying outcome when purchasing flexible plastic tubing from a flexible plastic tubing manufacturer, it is important to compare several companies using our directory of flexible plastic tubing manufacturers. Each flexible plastic tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each flexible plastic tubing business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple flexible plastic tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services