PVC, which stands for polyvinyl chloride, has increasingly replaced metal piping and tubing. Due to its strength, longevity, ease of installation, and low cost, PVC is among the most widely used plastics in the world. Square, rectangular, and cylindrical PVC tubes are just a few available shapes. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

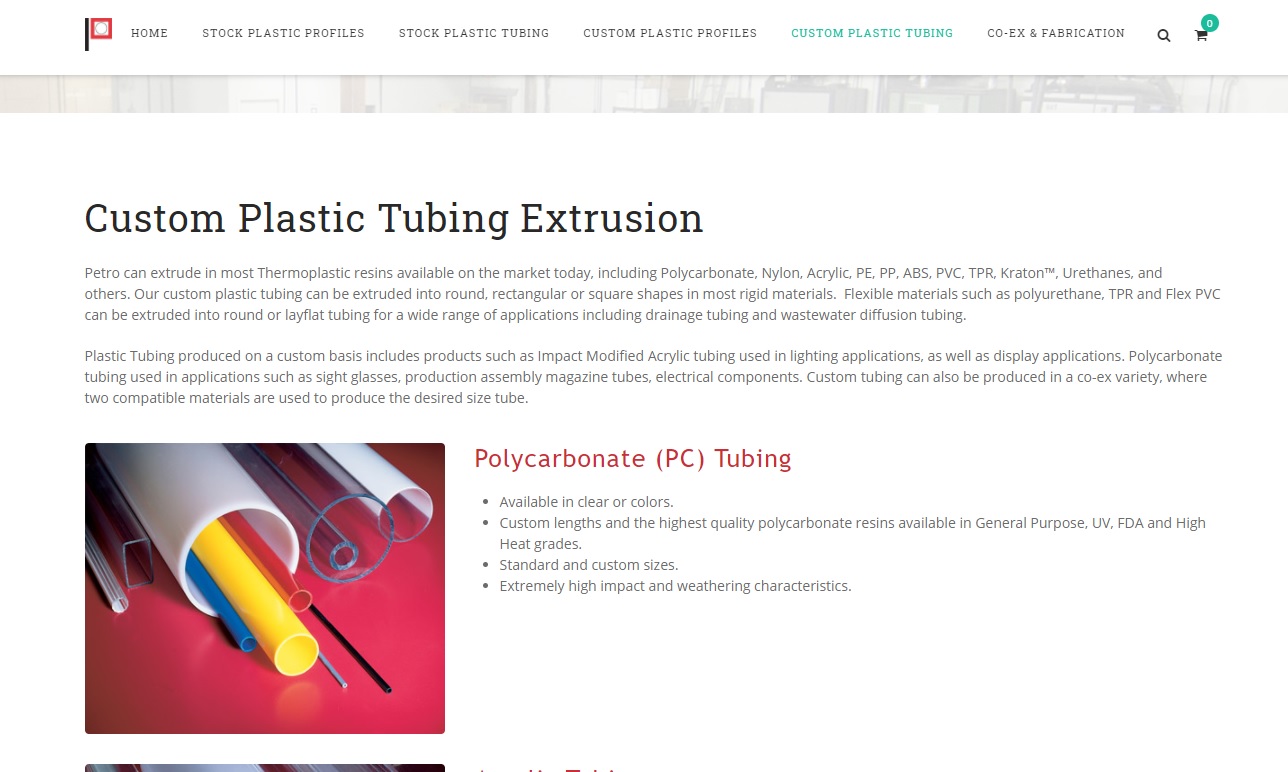

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

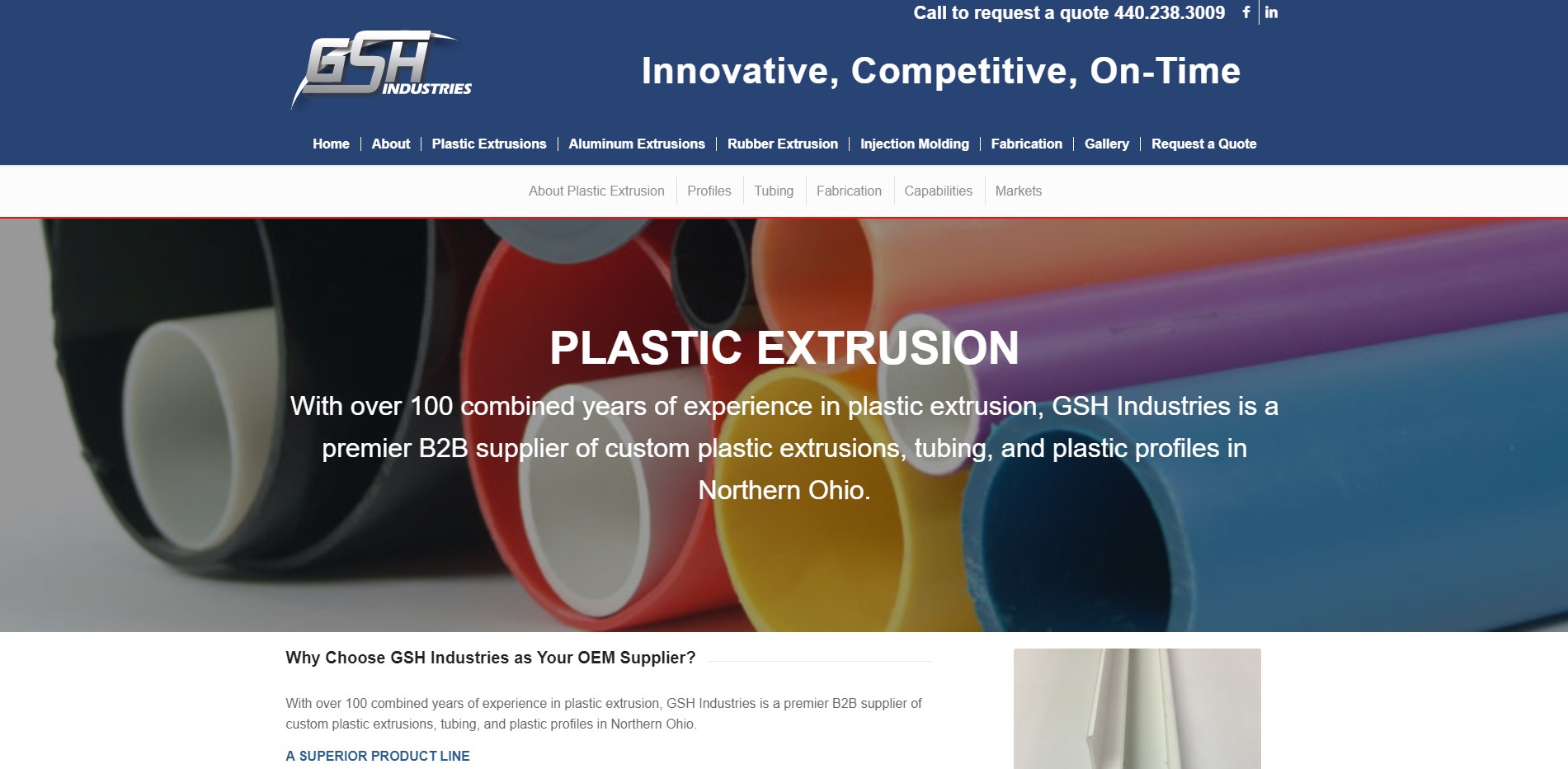

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

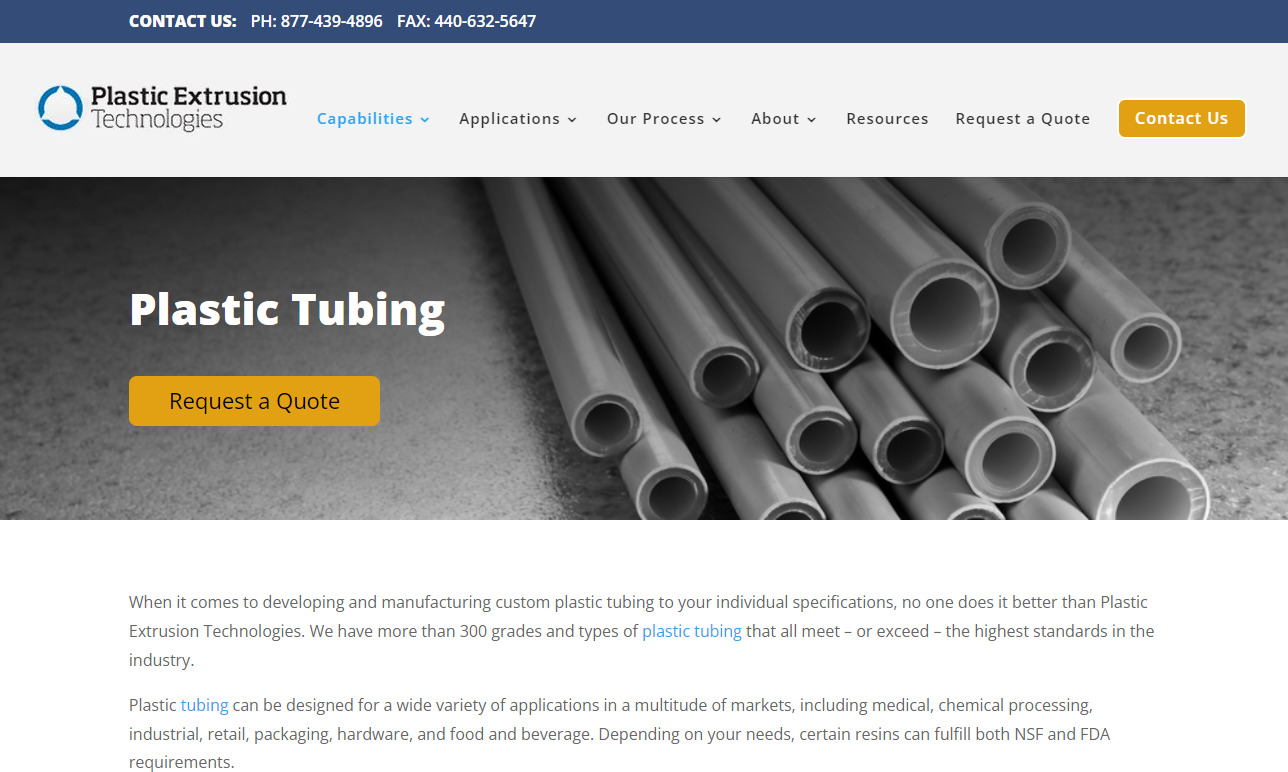

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More PVC Tubing Manufacturers

However, most people instinctively picture a circular piece of material when they think about tubing (pipes). Round PVC tubes are utilized in a wide range of applications, but moving fluids account for most of their use, and with good reason. PVC tubing is produced by extruding PVC as the raw material, and the process generally follows that of a standard pipe extrusion operation.

Types of PVC Tubing

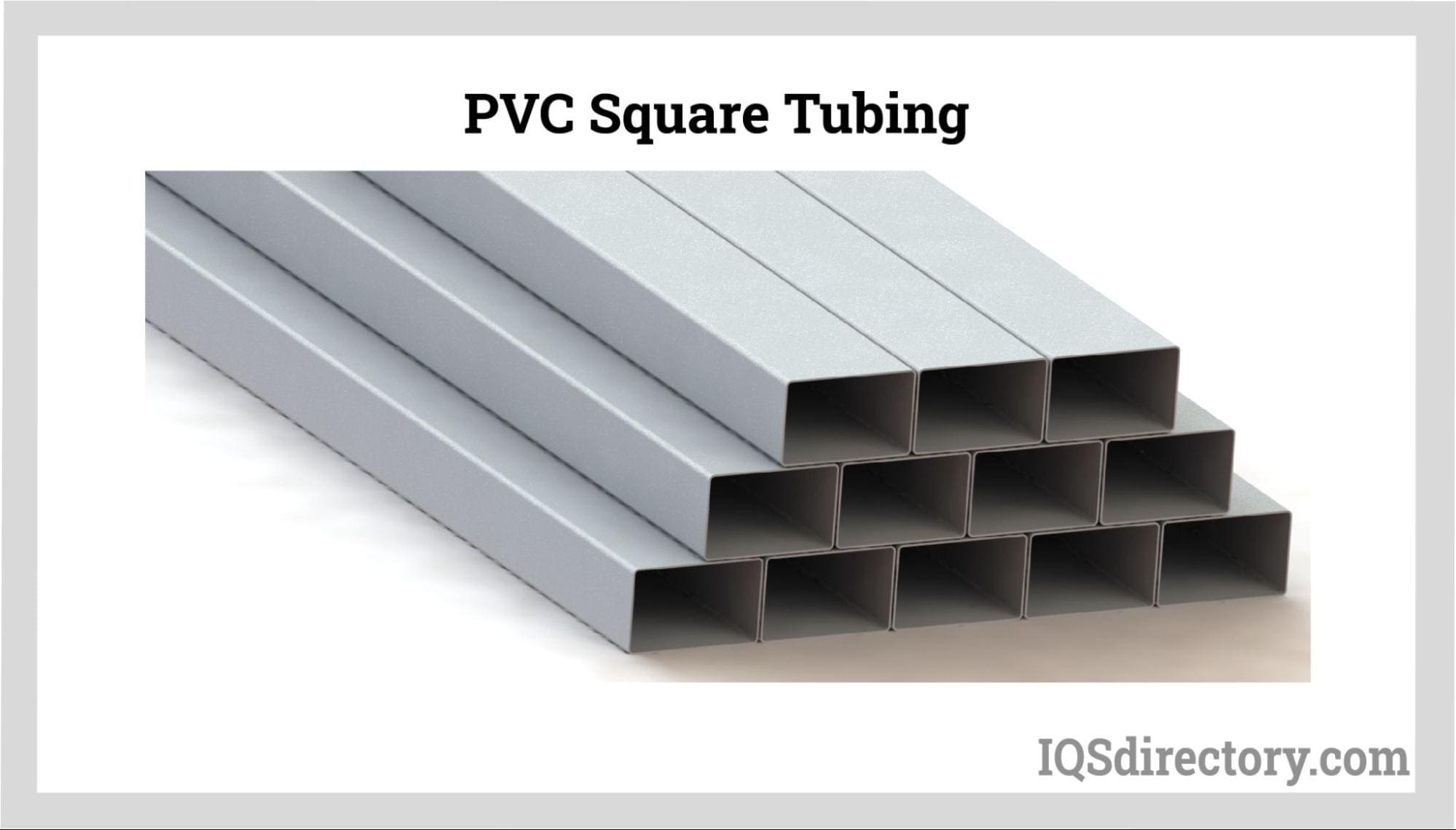

Square PVC Tubing

Square tubing performs better in some applications, although its shape doesn't encourage the notion that it is a tube. Square tubing's flat sides make it simple to attach fasteners and other items. It can also be constructed to be considerably smaller and closer to the surrounding objects, taking up less room. The PVC square tube is simple to produce and bind and has numerous industrial applications.

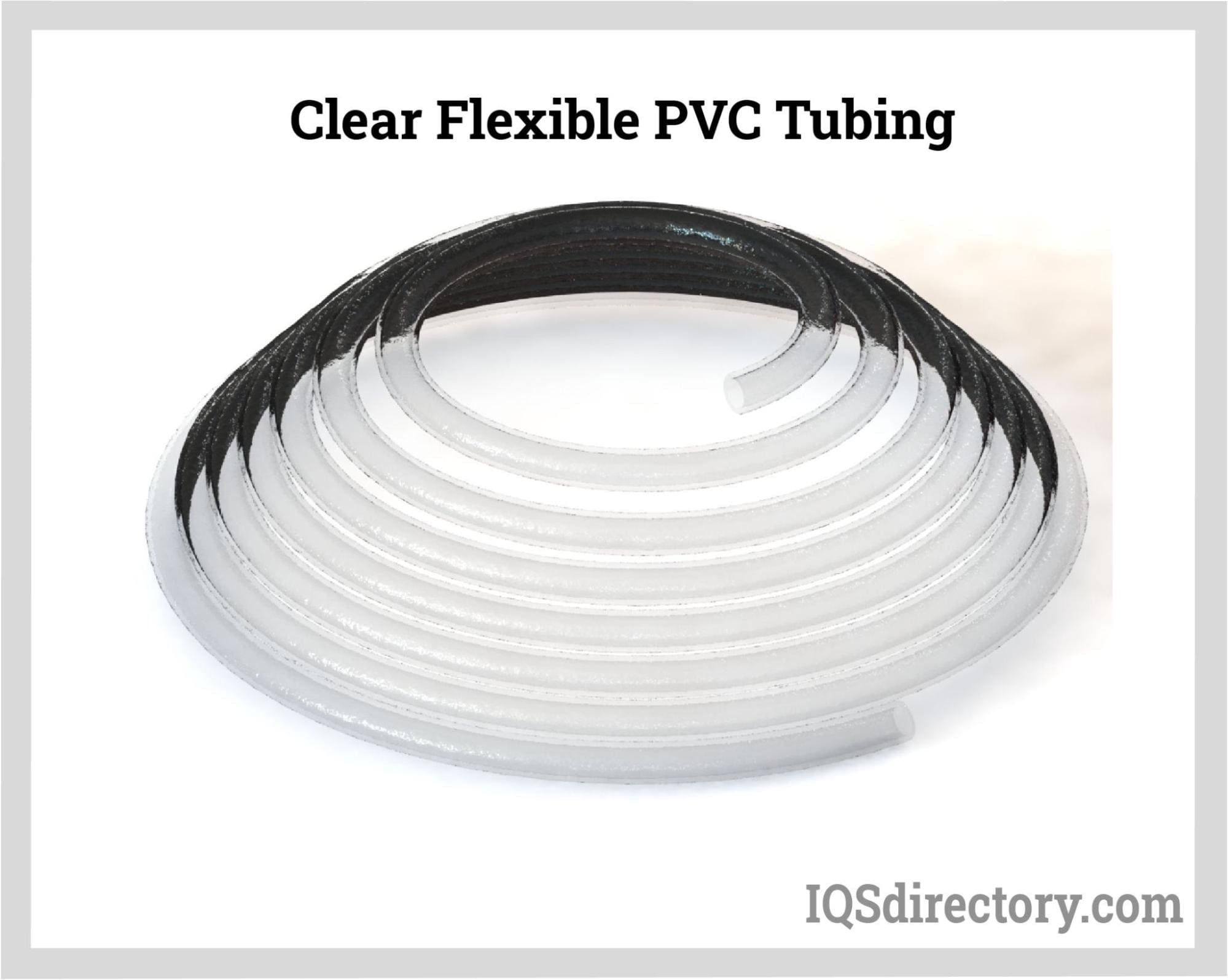

Flexible PVC Tubing

Flexible PVC tubing is a very versatile and affordable tube option. Typically, this is a clear PVC tube with a great flow rate and the advantage of complete transparency of the contents. In addition, they have excellent abrasion, corrosion, and chemical resistance levels, are flexible, and may be used with food, alcohol, oils, and chemicals. Other benefits of this tube include its resilience to abrasion, corrosion, and chemicals, its high flexibility, and its low toxicity composition, which gives no flavor or odor to the contents it transports.

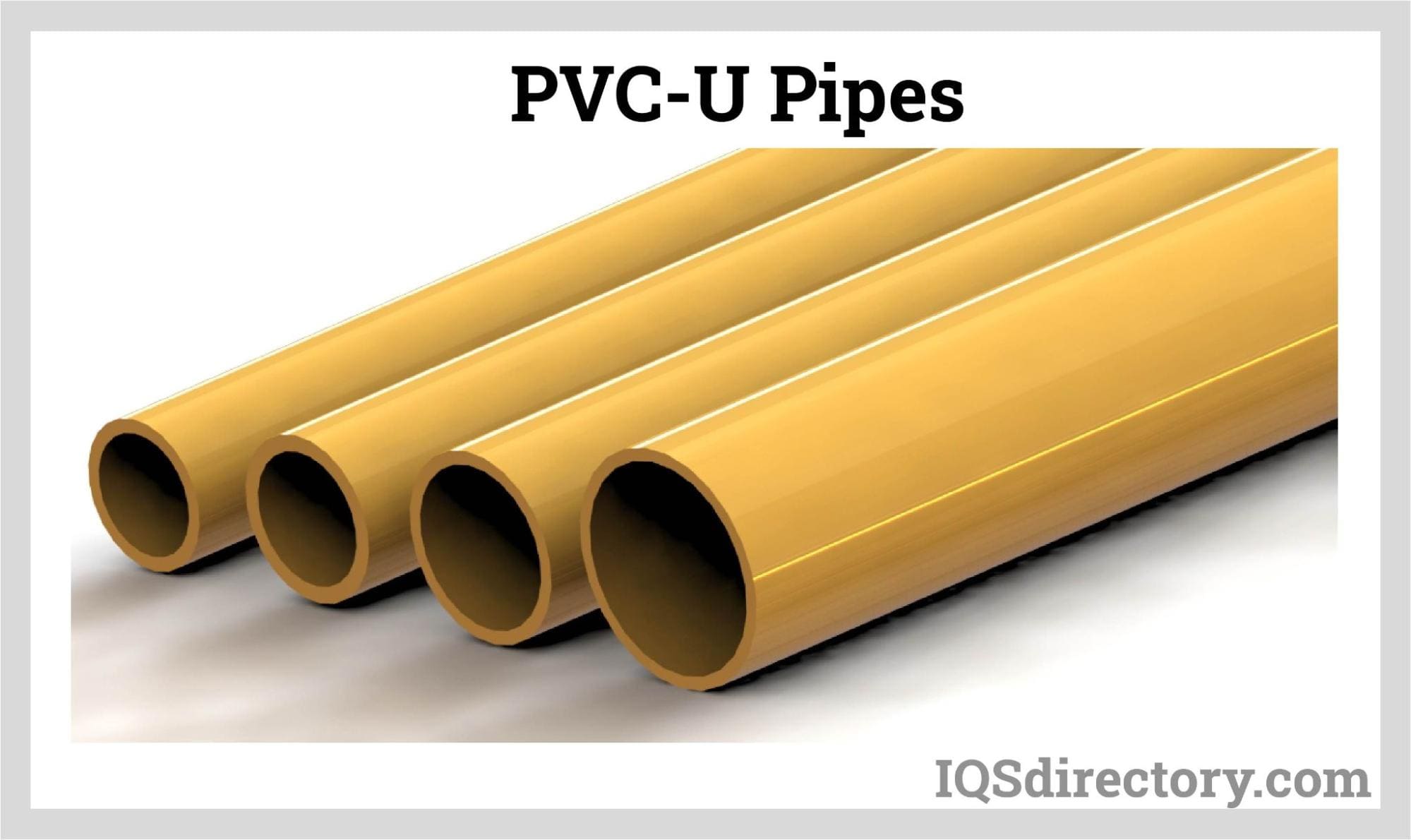

PVC-U Tubing

Unplasticized is what the "U" in PVC-U stands for. This “U” indicates that the plasticizer, a solvent added to PVC to make it flexible and less brittle, is not present in these PVC tubes. PVC-U is frequently referred to as stiff PVC because it doesn't contain this component. It is used to transfer both wastewater and potable water. They are 100% recyclable and light, making them convenient to handle, long-lasting, and economical.

PVC-O Tubing

PVC-O is molecularly oriented PVC. PVC-O acquires a layered structure throughout this production process, increasing its corrosion resistance. As a result, PVC-O has an ideal stiffness, strength, and flexibility ratio, making it advantageous for pressure pipes for drinking water, irrigation, and sewer pumping mains due to its high hydraulic capacity and longevity.

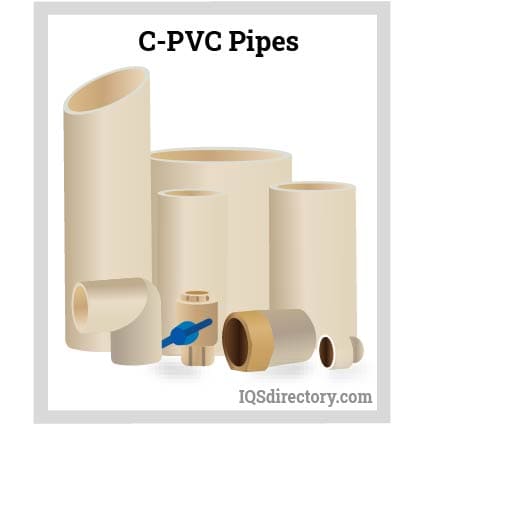

C-PVC Tubing

The traits of C-PVC are identical to those of PVC-U. It has great corrosion resistance and is designed to deliver drinking water. This type of PVC pipe is unique because it can endure a broader range of temperatures than conventional PVC due to chlorination. C-PVC is frequently employed in both residential and commercial construction as a result.

PVC-Hi Tubing

PVC-Hi, or high-impact PVC tubes, are regular PVC tubes modified to increase their resistance to outside impacts. It typically consists of a blend of materials, including PVC, to boost its durability. It must be resilient over the long term and capable of working well under duress. Before a tube can be formally referred to as PVC-Hi, it must adhere to several criteria and laws. This tube is primarily used to transmit highly volatile natural gas, so it must adhere to numerous restrictions.

Applications of PVC Tubing

- The water supply sector uses PVC pipes extensively. The majority of the main water pipelines are made of PVC tubes. In addition, PVC pipes are used in both extensive irrigation systems and sanitary sewer networks.

- PVC tubes are used in plumbing, drainage, agricultural irrigation, power & telecommunications systems, and the ductwork of heating and cooling systems in home and commercial settings.

- Utility companies employ underground PVC pipes with bigger diameters and thicker walls to bring drinking water to a network of homes and businesses.

- To transport hot water, heating, ventilation, and cooling systems employ C-PVC tubes. Likewise, these PVC pipes transport cold water in HVAC systems.

Benefits of PVC Tubing

- PVC tubes are the preferred method for transporting water and power in many industries. The major reasons for their widespread use are their strong resistance to heat and corrosion.

- Compared to concrete and metal, PVC has less friction because of its smooth surface. As a result, it is a desirable material for pipelines that transport water.

- It is portable and simple to move over long areas to lay pipes.

- Since a relatively straightforward procedure is employed for its mass manufacture, it is cost-effective.

- It is resilient to high levels of stress and robust and long-lasting. This trait qualifies it as a good material for underground pipes and pipes carrying pressured fluids.

- PVC's inertness, or resistance to chemical interactions with other compounds, is a beneficial chemical feature. As a result, drinking water and water used for household purposes can now be transported without risk.

Choosing the Correct PVC Tubing Supplier

To make sure you have the most productive outcome when purchasing PVC tubing from a PVC tubing supplier, it is important to compare at least 4 suppliers using our PVC tubing directory. Each PVC tubing supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each PVC tubing business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple PVC tubing businesses with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services