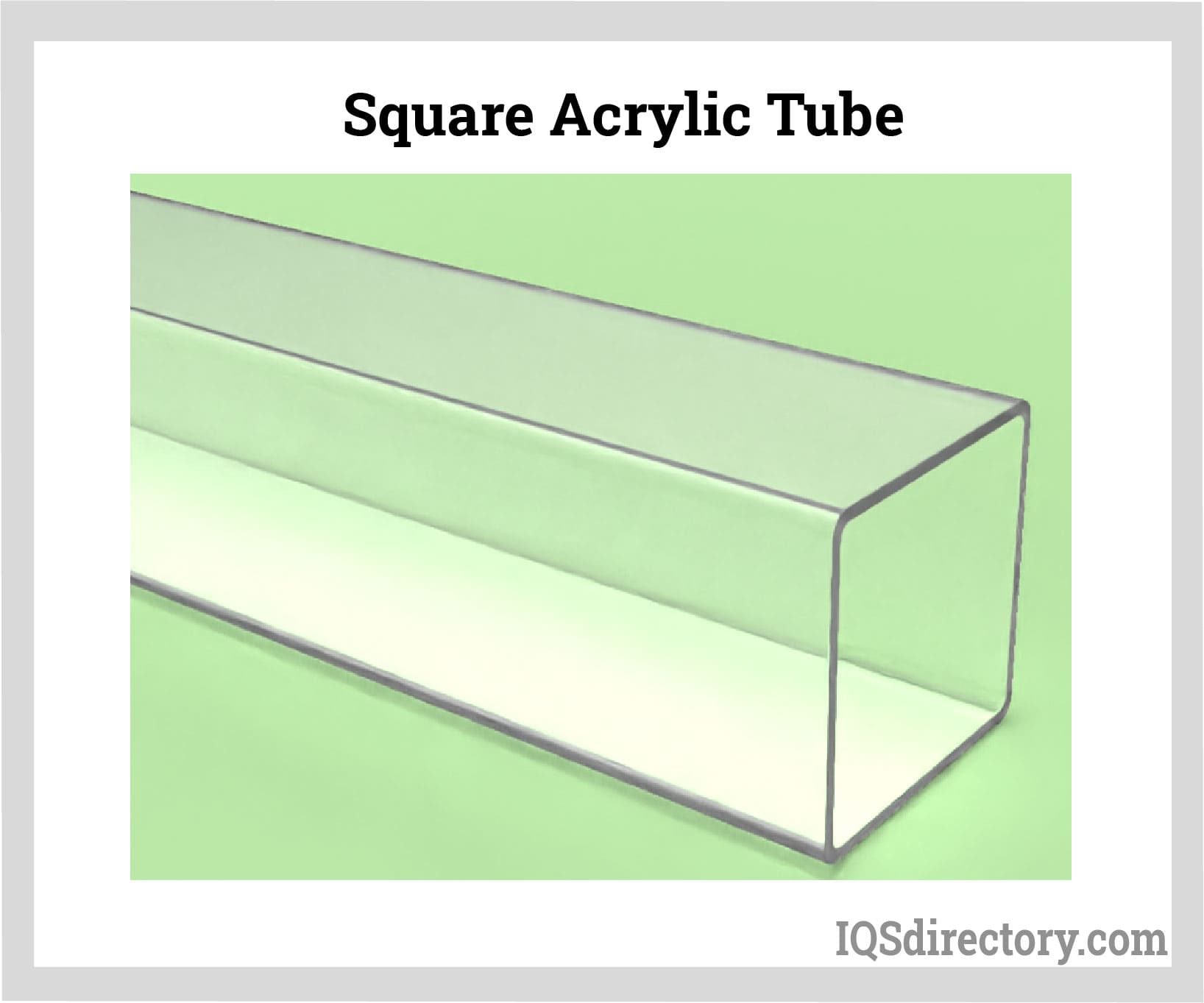

Simply put, an acrylic tube is a type of plastic tubing. Like any material that falls under “acrylic,” acrylic tubes are made from acrylic resins, which are produced by mixing pure acrylic acid with several additional ingredients. Acrylic resin is a highly sought-after material for plastic tubing since most of it is transparent or translucent. Thermoforming, or using heat to shape the material into a useful plastic product, is primarily used to create acrylic resins. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Acrylic Tube Manufacturers

Types of Acrylic Tubes

Extruded

Raw acrylic resin is poured into a hopper suspended above an extrusion machine during the extrusion process. Then, a conveyance channel is emptied of the raw material. The channel has a lengthy screw mechanism and heating components. The resin is melted to a molten state and forced toward a die by the friction created by the spinning screw and heat produced by the heating components. A die is a device used to mold material into a particular shape. By the time the molten material exits the machine after being driven into the die, it has assumed a tubular shape.

The tube can be cut and shipped for further processing or made ready for shipping after it has cooled. This procedure guarantees homogeneity in the finished product and gives the tube some leeway in length. Due to the amount of manipulation, the material has the potential to be scratch-prone. The extrusion process is the most effective and efficient of all fabrication techniques.

Cell Casted

In a far more straightforward procedure known as cell casting, molten plastic is poured into a mold. The finished tubing product can only be as long as the molding cell because it is a non-continuous operation. However, the material will be less likely to scratch due to the straightforward method and minimal material handling. Even though the extrusion method is significantly more dependable, extensive study is being done on the molecular makeup of plastic and cell casting itself to uncover more benefits.

Applications of Acrylic Tubes

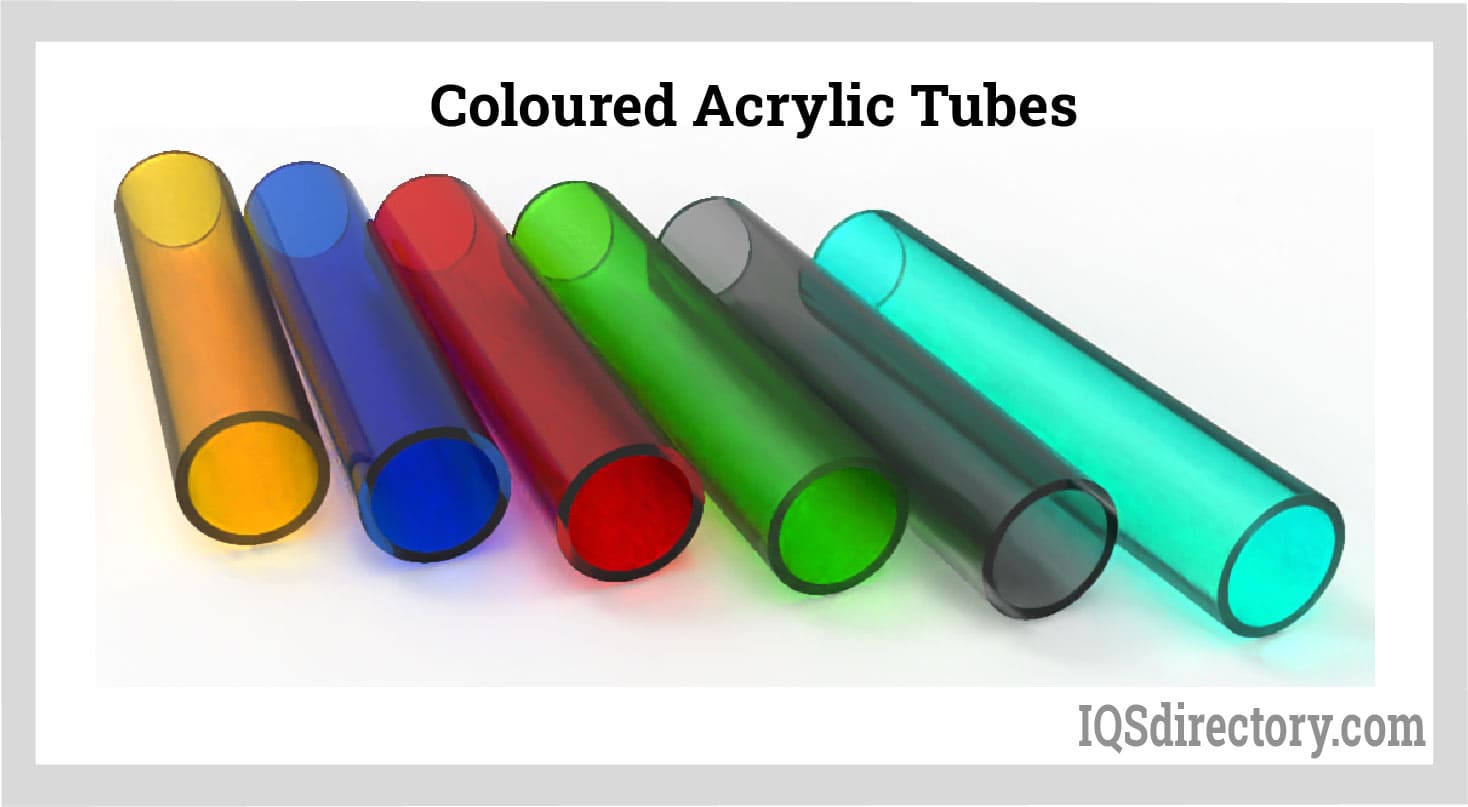

In homes, acrylic tubing is used in some applications. For example, acrylic tubing can be a long-lasting and attractive replacement for many household items like curtain rods. Acrylic tubing can be customized in a wide variety of ways. Some applications could benefit from tubing that is colored or has different levels of transparency. Acrylic tubes can be produced in various colors, including fluorescent ones, and have frosted, pearl-like, glossy, or clear textures. Colored tubes are very advantageous to the lighting business.

They enable brilliance and a clear view of details in many displays and can help illuminate a space in a specific color. There are several instances where acrylic tubing is a better material than glass from an economical and functional standpoint. Lighting, furniture, lab equipment, product design, museum exhibits, surgical gadgets, and children's toys are a few examples of situations where acrylic can perform better than glass. Glass tubing offers far less insulation, can weigh twice as much, and is much less impact-resistant.

Additionally, glass can acquire a greenish tinge when manufactured for thickness. However, acrylic does not suffer from this condition and has considerably better visibility. The biomedical, fine arts, architecture, utilities, manufacturing, food and beverage, commercial, and maritime sectors employ acrylic tubing extensively. The wide range of sectors that employ acrylic is evidence of its dependability for carrying out difficult operations.

Advantages of Acrylic Tubes

Easy to Fabricate and Shape

Acrylic tubes may be molded into various shapes and become bendable when heated. Acrylic material retains its created shape as it cools, making it possible to mill, drill, or saw it just like wood. Molds made of wood or plastic can be used to shape it, which is relatively affordable for manufacturers. Acrylic is a thermoplastic that can be molded into almost any shape since it softens at high temperatures.

Highly Transparent

As acrylic plastic ages, it doesn't become very yellow-tinted and keeps its transparency. For applications that are exposed to sunlight, this is crucial. The light transmittance of acrylic plastic is equal to glass and has more fade resistance than other plastics, making it more trustworthy and long-lasting. It is ideal for plexiglass windows, car screens, laptops, eyewear, tanks, and more items.

Simple to Maintain

Although there are some guidelines for cleaning and caring for acrylic, it's a simple material to maintain. To clean it, use a moist microfiber towel and dab areas with light imperfections and debris. In addition, it's crucial to ensure all dirt and grit are removed from a cleaning cloth because accidentally pressing gritty dirt or undesired particles into acrylic might cause it to scrape even more.

Choosing the Proper Acrylic Tube Manufacturer

To ensure you have the most positive outcome when purchasing acrylic tubes from an acrylic tube manufacturer, it is important to compare several companies using our directory of acrylic tube manufacturers. Each acrylic tube manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each acrylic tube business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple acrylic tube companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services