Nylon tubing is a special type of polyamide resin tubing. This material is notable for its dimensional stability and chemical, abrasion, impact, and moisture resistance. Pneumatics, food processing, vehicle manufacturing, and robotics are all businesses that use nylon tubing. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

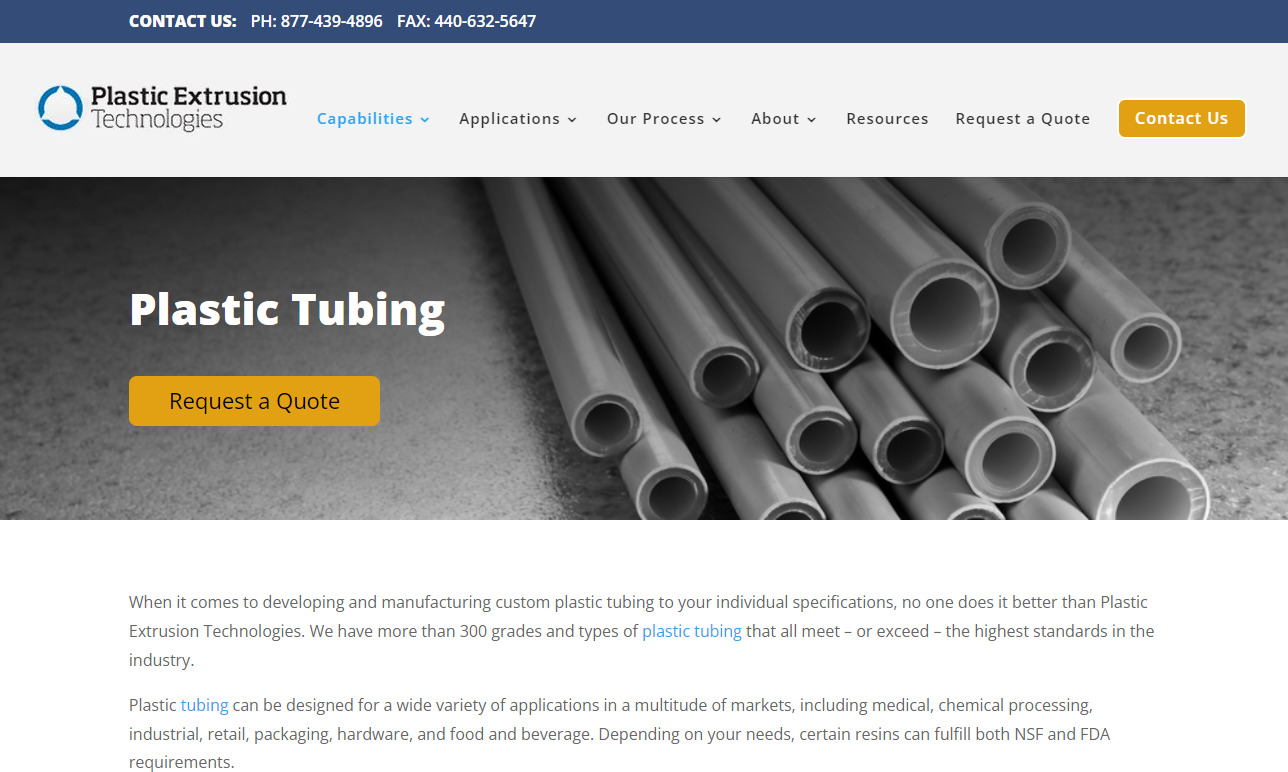

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Nylon Tubing Manufacturers

What is Nylon Tubing?

Nylon tubing is a special type of polyamide resin tubing. This material is notable for its dimensional stability and chemical, abrasion, impact, and moisture resistance. Pneumatics, food processing, vehicle manufacturing, and robotics are all businesses that use nylon tubing.

How Nylon Tubing is Made

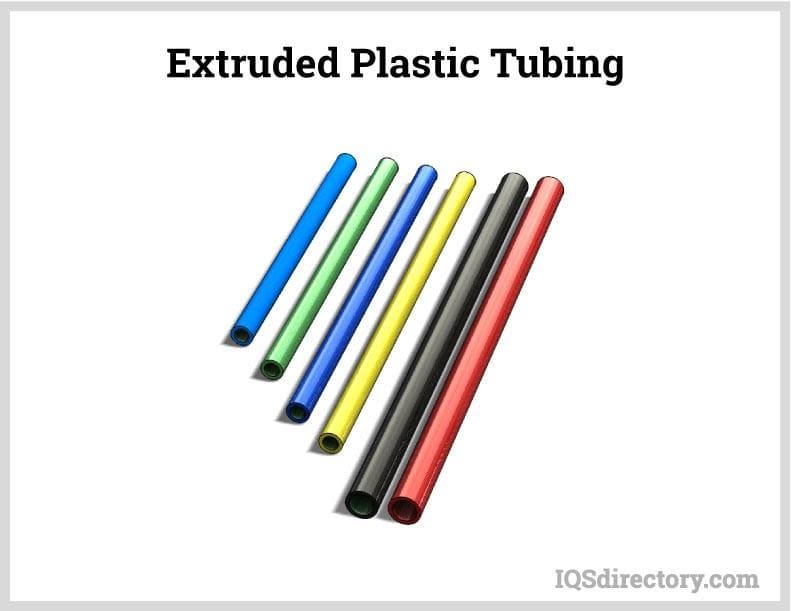

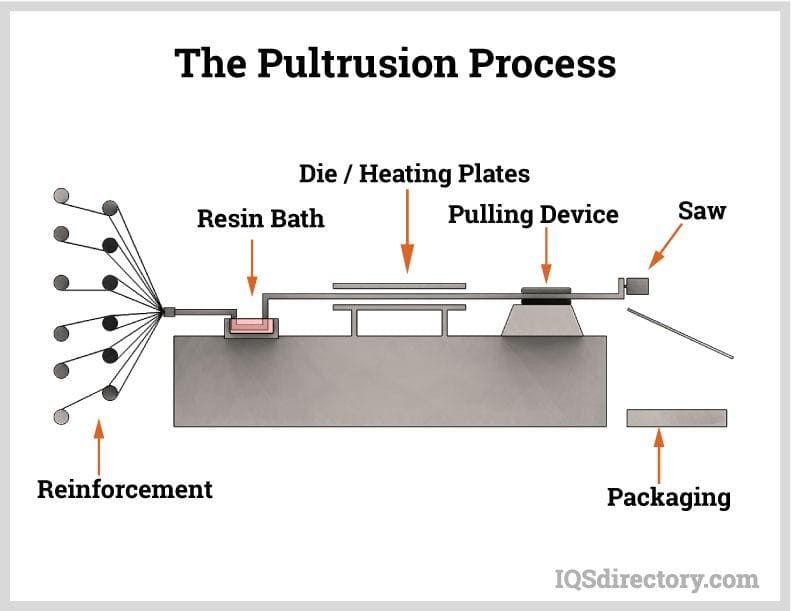

Extrusion and pultrusion are the two ways of making plastic tubes. They differ in the way the molten plastic travels through the die. In extrusion, the molten plastic is pushed through the die while it is dragged through in pultrusion.

Extrusion

The major ingredient is polymer resin, which is supplied into a hopper located on the extruder's barrel as nurdles, pellets, granules, flakes, or powder. The resin flows from the hopper's feed throat into a barrel with a screw that propels the resin toward the die.

The resin is gently heated to a melting point as it moves down the barrel, pushed along by the screw. Temperature, speed, force, tension, and time are all controlled by sophisticated extrusion equipment.

Extrusion is used to create both flexible and rigid tubing. Two or more materials can be mixed in coextrusion to create tubing with a stiff core and a flexible outside.

Pultrusion

Pultrusion, like extrusion, is a continuous-feed method for creating tubular profiles. Pultrusion, unlike extrusion, pulls reinforced fibers through a die after they have been wetted with a thermoplastic resin.

As the fibers pass through the die, they polymerize. Pultrusion is a low-maintenance, high-efficiency technology for making corrosion-resistant, low-thermal-conductivity plastic tubing.

Types of Nylon Tubing

The types of nylon tubing include:

Standard Nylon Tubing

Nylon 6 is the most commonly used type. It is more corrosion resistant than other forms of nylon tubing because it resists moisture. Nylon 6 is made up of a single monomer, a simple molecule with two or more binding sites for other monomers. Because standard nylon is made up of six carbon atoms, it's known as nylon 6.

Nylon 66 Tubing

Nylon 66 is a kind of nylon commonly used alongside nylon 6. Both are similar, but they have distinct features due to differences in chemical structure. Nylon 6 is made up of a single monomer containing six carbon atoms, whereas nylon 66 is made up of two monomers.

Between the two polymers, there are major variances. Nylon 6 is more resistant to stress and shock, shrinks less in the mold, and is easier to color.

Nylon 66 has a stronger crystalline structure, making it more resistant to acids and chemicals while absorbing less water. Nylon 66 is also more heat resistant than nylon 6.

DOT Nylon Tubing

Because of its name, this type of nylon tubing is required to comply with the Department of Transportation. This designed polyester blend tubing is utilized in car brake lines because it stays more flexible for longer than standard nylon tubing.

It can withstand greasy, hot, and cold temperatures, ranging from -85 °F (-65 °C) to 200 °F (93 °C). In addition, DOT tubing is abrasion- and vibration-resistant, as well as flexible, lightweight, fatigue-resistant, and dimensionally stable.

High Pressure Nylon Tubing

High-pressure nylon tubing is designed for a variety of applications. It can handle natural solvents, alkali solutions, hydraulic fluids, oils, and even weak acids. It's tough, rigid, and abrasion-resistant, especially in high-heat, high-pressure, or high-vibration settings.

Nylon tubing with higher tensile strength is employed in the chemical, vehicle, and transportation industries, notably for industrial applications.

Flexible Nylon Tubing

Flexible nylon tubing is known as "super soft" because it is made from nylon 11 resin, which has a unique component that improves flexibility greatly. It possesses several qualities that help it maintain its dimensional stability and resist abrasion, chemicals, moisture, impact, and heat.

Nylon 11 tubing is manufactured from castor beans and is suited for applications where polyurethane isn't viable, such as coolant and refrigeration lines.

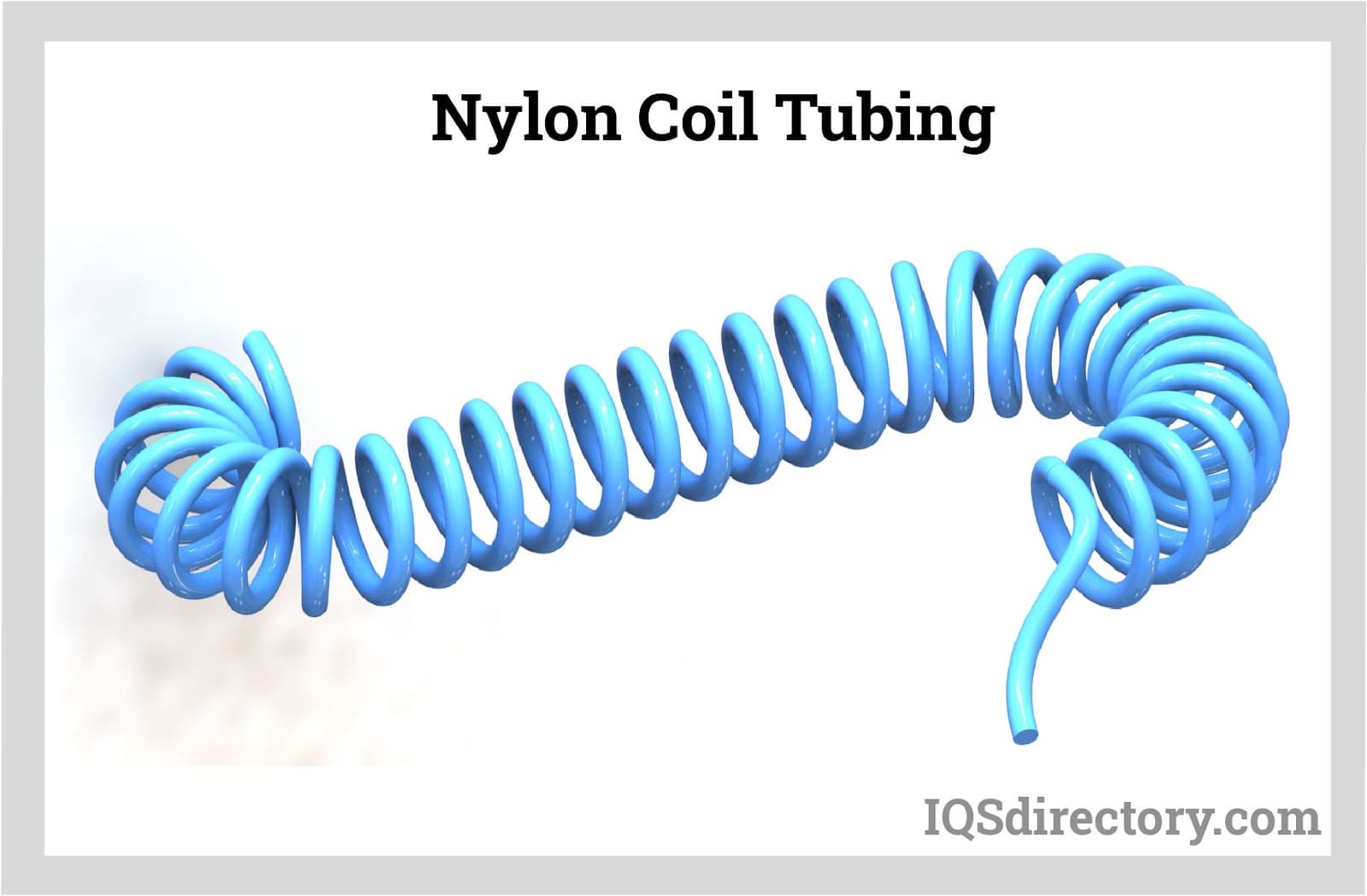

Nylon Coil Tubing

These spirals of nylon tubing are coiled in expanding lengths to make them more flexible, and they're frequently used to transport compressed liquid or air over short distances.

Nylon coils self-retract and lengthen, making them a cost-effective and lightweight choice for air supply to pneumatic machines.

Because its nylon tubing won't harm the paint, it's perfect for use with articulated brake coils in semi-trucks. This type of nylon tubing is also utilized to help with animal feeding and watering.

Choosing the Correct Nylon Tubing Supplier

To ensure you have the most constructive outcome when purchasing nylon tubing from a nylon tubing supplier, it is important to compare several companies using our directory of nylon tubing suppliers. Each nylon tubing supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each nylon tubing business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nylon tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services