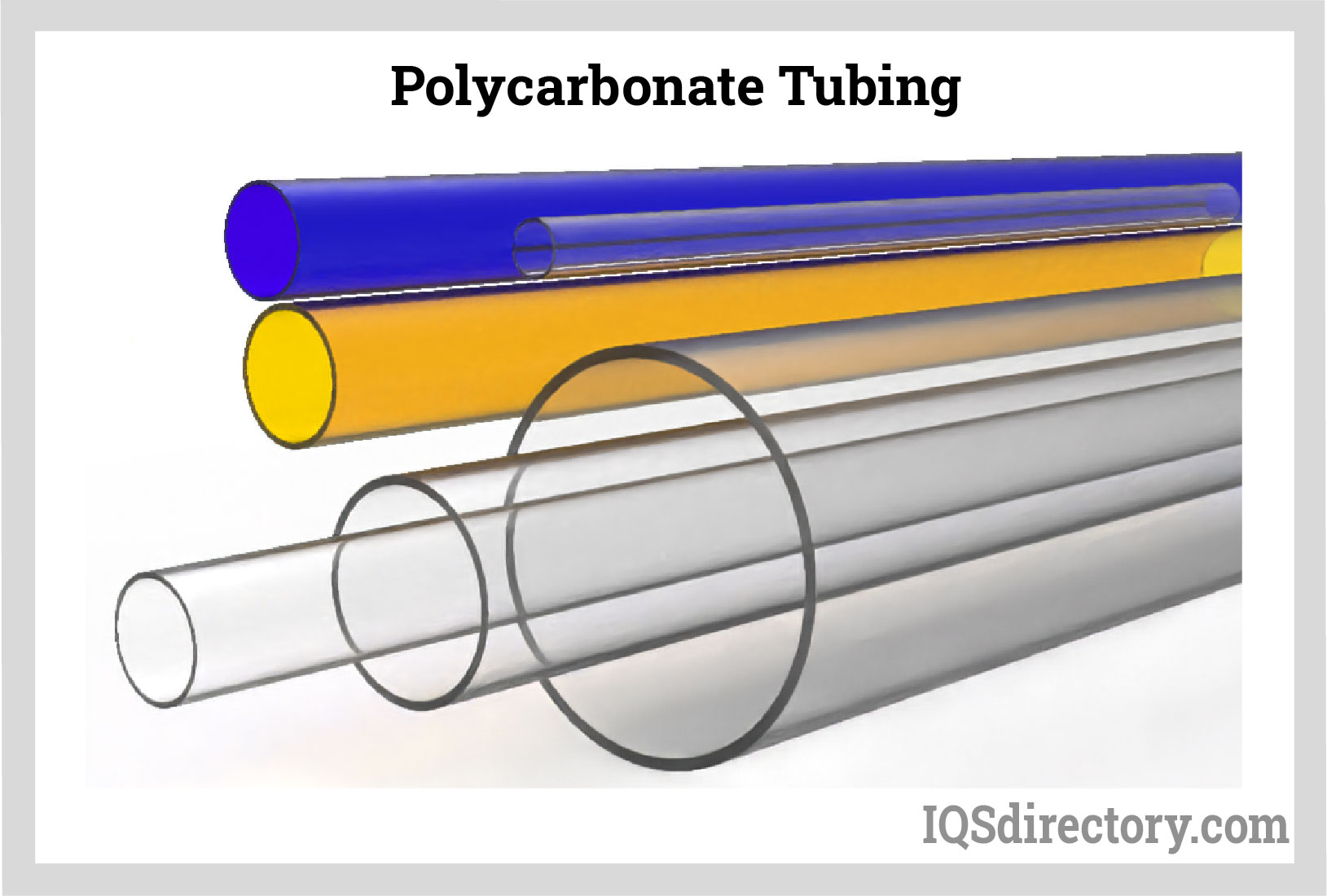

Polycarbonate tubing is a versatile and dependable material that combines glass’s transparency with plastic’s impact resistance. Due to its great resistance to substances like acids, oils, and greases and variations in humidity, polycarbonate is a highly applicable material for more demanding applications. Polycarbonate tubing is a viable replacement in situations where acrylic tubing is not appropriate. These uses can involve heavy goods, food chutes, or pressure chambers. Read More…

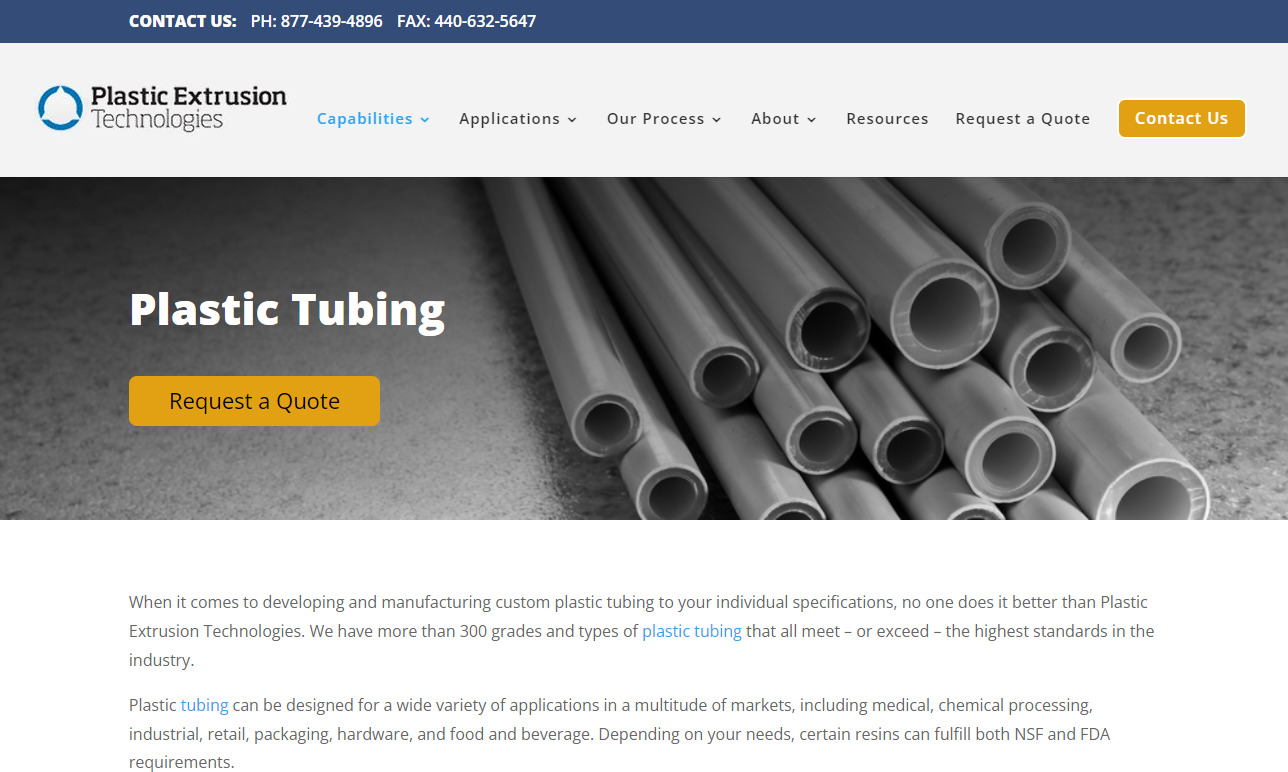

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

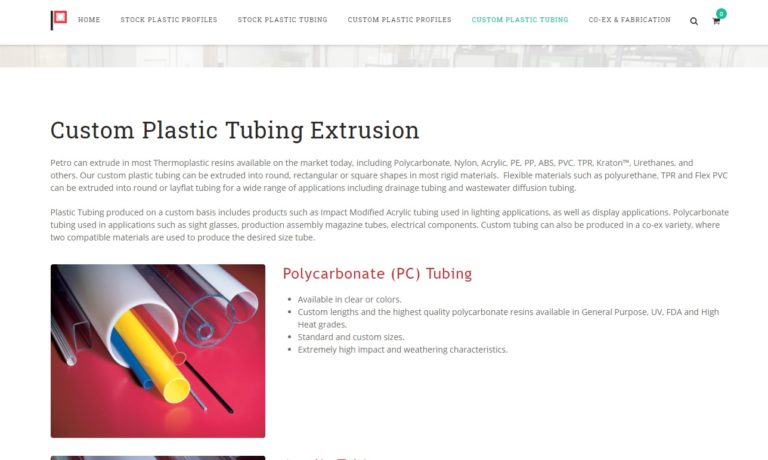

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Polycarbonate Tubing Manufacturers

Polycarbonate tubes are excellent in insulating applications and resistant to flame and high temperatures. The tubes are bonded with adhesives or solvents and easily sawed, chopped, drilled, and machined.

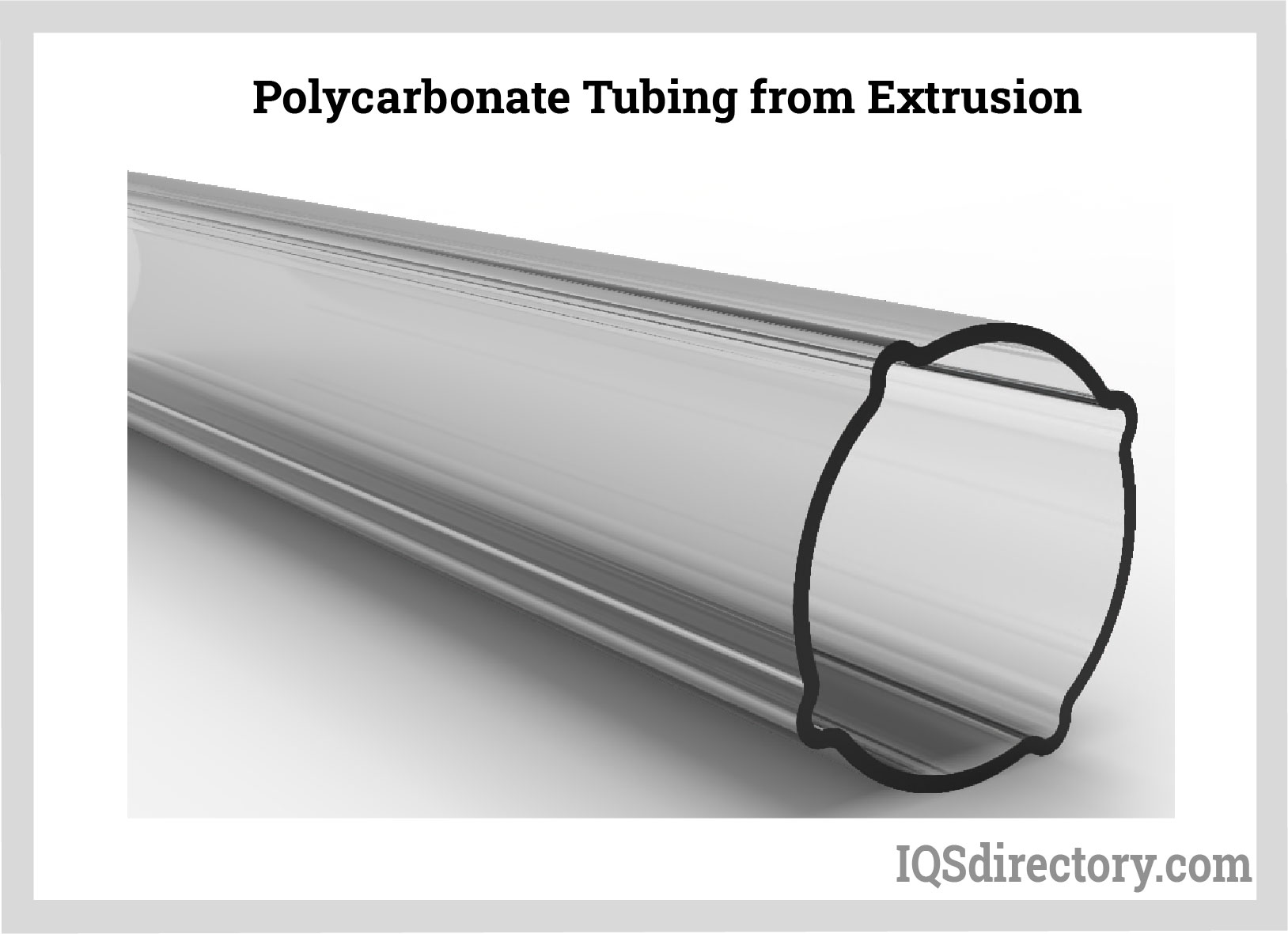

Creating Polycarbonate Tubing

Extrusion is a method used to make polycarbonate tubes. A conveyance channel with heating elements and a screw mechanism, a hopper that hangs overhead and retains the raw material, and a die situated at the end of the conveyance channel that molds the plastic into a tubular configuration are all used in the extrusion process. The raw material is poured out of the hopper and into the conveyance channel in the first step of the procedure. Next, the raw material, or stock, is heated and reduced to molten material by friction and heat applied by the rotating screw mechanism and heating elements inside the channel. The freshly manufactured tube is either dispatched for additional processing or is ready for direct transport after cooling.

Polycarbonate Tubing Benefits

Making polycarbonate tubes is inexpensive and requires little energy. They are robust, can be produced in a range of colors and levels of transparency, can be as translucent as glass, and make excellent insulators. Polycarbonate tubes are valuable in weight-sensitive applications due to their lightweight nature, amazing strength, and insulating qualities. Polycarbonate is a dependable material. It has a great degree of clarity and is half as heavy as glass.

Although it is more impact-resistant than glass, polycarbonate is about 250 times stronger than glass. In contrast, acrylic can withstand temperatures between -30° Fahrenheit and 190° Fahrenheit (or approximately -34.4° Celsius and 87.8° Celsius). Even if a conventional drill bit is used to drill close to the borders of polycarbonate, it usually won't crack. However, drilling acrylic close to the edge or using a drill bit not made for plastic will cause it to crack. Acrylic can burn slowly, while polycarbonate has a significantly reduced flammability and is more appropriate for places with flames.

Compared to acrylic, polycarbonate is substantially more resistant to chemicals. Despite the ease of cleaning both materials, polycarbonate requires less specialized cleaners than acrylic. Acrylic should be washed with gentle soap and water, although polycarbonate can be cleaned with harsher chemicals like ammonia.

Polycarbonate Tubing Drawbacks

There are several situations where acrylic is preferable to polycarbonate. First, while acrylic has a 92% light permeability, polycarbonate has an 88% light transmission. Second, acrylic can be polished to restore clarity and smooth the edges, but polycarbonate cannot. Third, polycarbonate is less heat resistant than acrylic.

Despite polycarbonate tubing's resilience, it must be handled carefully to ensure proper usage. The tubes could also be prone to scratching and abrasion. However, giving the tube's exterior a strong covering can readily avoid this issue.

Applications of Polycarbonate Tubing

Glass can be replaced by polycarbonate, which is also a widely desired material for developing and manufacturing numerous products across many industries. Compact disks, bulletproof windows, LED tubing, flow lines, electronics packaging, data storage, building supplies, and medical equipment are a few of this material’s numerous products.

One particular instance is the vision sector, where polycarbonate significantly impacts. Transparent, highly robust, and with a high refractive index is polycarbonate. A substance's capacity to bend light is determined by its refractive index, which ranges from high to low. These features make polycarbonate the most widely used material today for producing corrective lenses. The aerospace, automotive, and architectural industries are a few others where polycarbonate tubes excel at producing various parts.

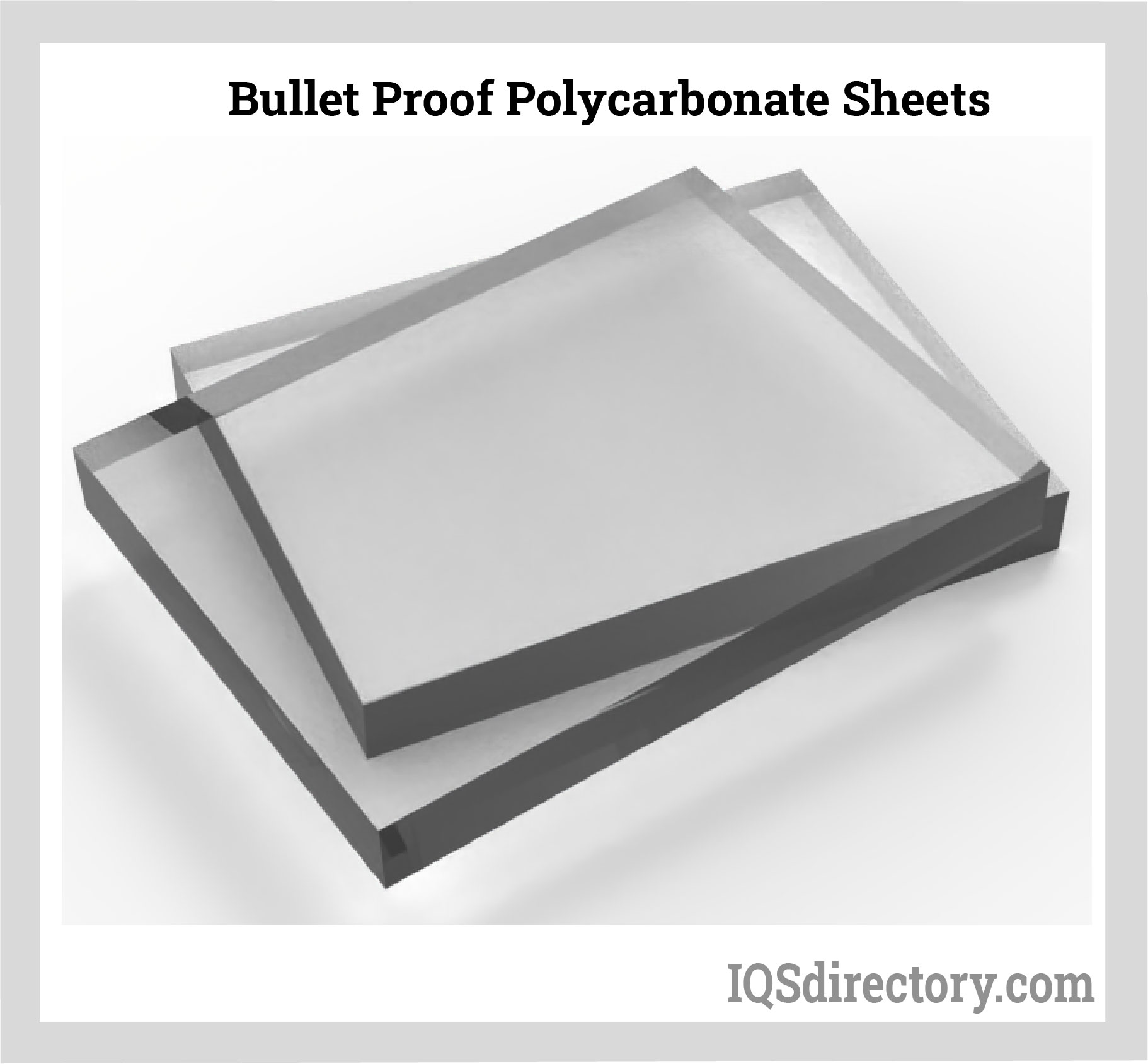

Since polycarbonate is a thermoplastic, its material characteristics can be created and reformed as it is heated with little loss. It can therefore withstand moderately high heat and, if necessary, be remolded. Polycarbonate is a top choice for many injection molding applications due to its robustness under demanding heat conditions. In this manufacturing process, liquid thermoplastics are pressed into a mold and chilled to solidify their cast shape. In extrusion molding, polycarbonate also works well when the heated resin is pressed through a die to create an elongated structure like a tube or pipe. The high level of mechanical strength of polycarbonate is another benefit. This mechanical strength makes it an excellent material for use in impact-resistant products like helmets or sturdy plastics, but it also has some unexpected uses.

Polycarbonate can be used to create bulletproof glass, which can be used to shield teller windows in banks and other establishments against projectiles. Polycarbonate is the perfect material for protecting what matters most because of its excellent mechanical strength and transparency. Durable polycarbonate sheets have sufficient strength to be employed in the construction industry for various structures, including canopies, roof domes, and roofing materials for sports stadiums.

Choosing the Proper Polycarbonate Tubing Supplier

To ensure you have the most constructive outcome when purchasing polycarbonate tubing from a polycarbonate tubing supplier, it is important to compare several companies using our directory of polycarbonate tubing suppliers. Each polycarbonate tubing supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each polycarbonate tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polycarbonate tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services