Poly tubing is a very flexible, lightweight, and long-lasting tube constructed from polyethylene, a polymer created by polymerizing ethylene. It’s a multipurpose tubing with strong walls that won’t break or split. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are the two most common forms of poly tubes (LDPE). Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

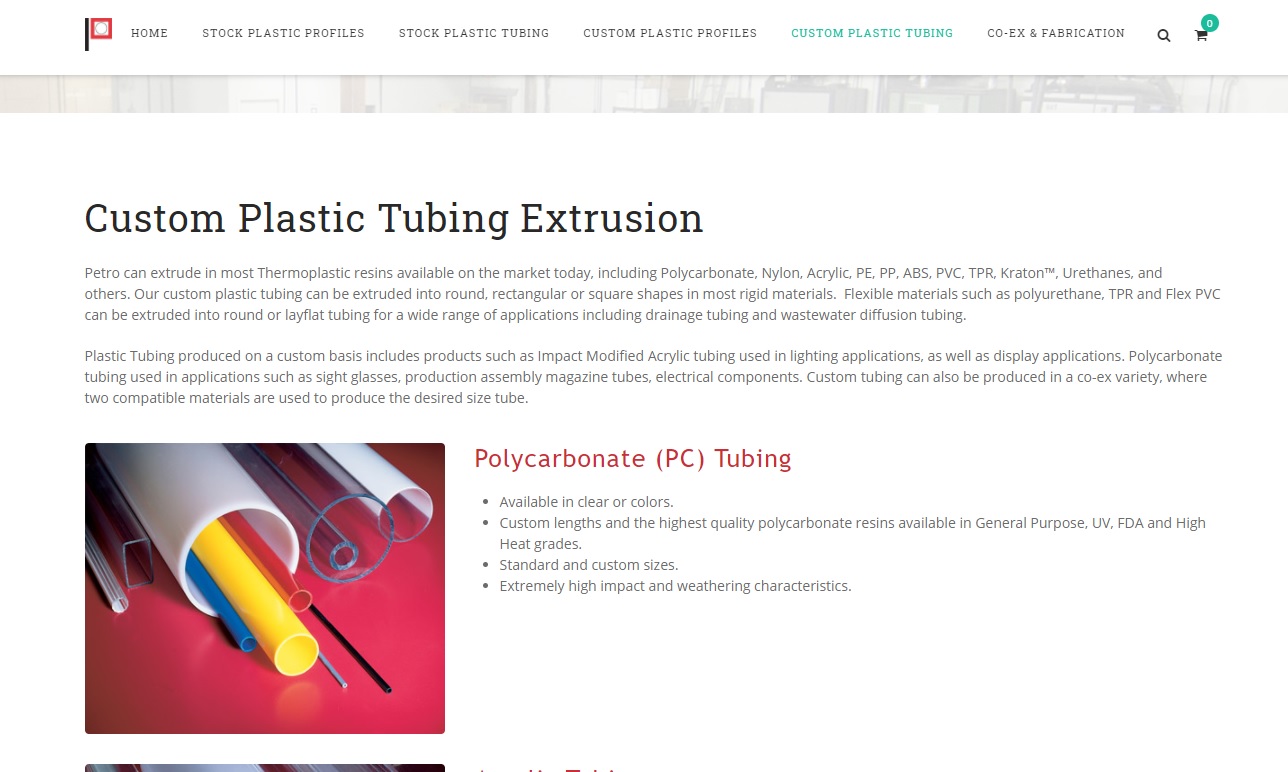

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Poly Tubing Manufacturers

What is Poly Tubing?

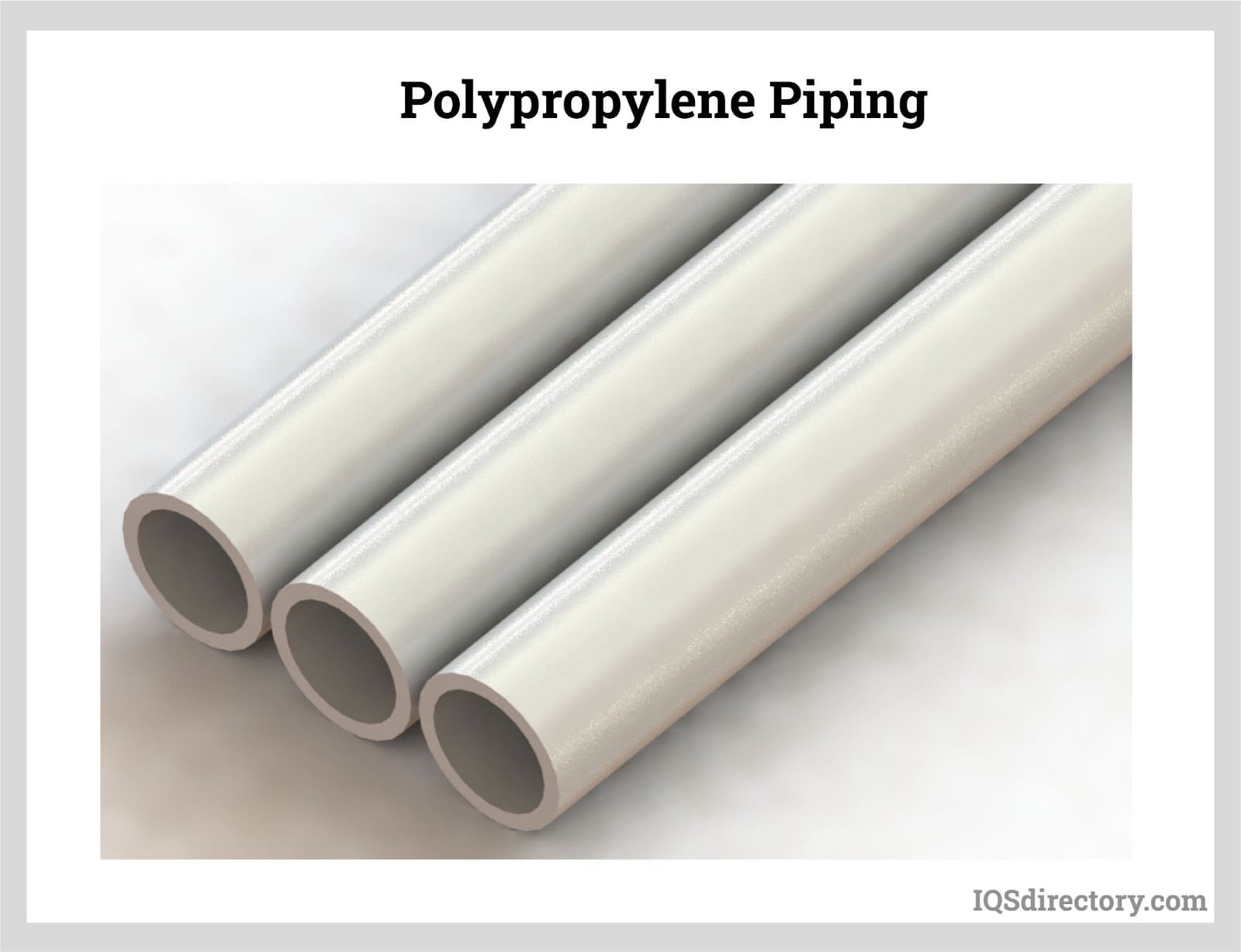

The fundamental distinction between HDPE and LDPE is flexibility; LDPE is extremely flexible, whereas HDPE is extremely hard and durable. LDPE and HDPE are both strong and resilient, regardless of their differences. Among the methods for producing poly tubing, extrusion is the most commonly used.

How Poly Tubing is Made

Polyethylene is a polymer chain of ethylene molecules, including carbon and hydrogen, used to manufacture poly tubing. The intended application determines the final thickness and density of polyethylene.

The material's wall thickness and stiffness define the poly tubing classification. HDPE and LDPE are the two main types of poly tubes, with HDPE being more hard and inflexible and LDPE being more elastic and forgiving. Both types of polyethylene begin with introducing heat to petroleum, regardless of thickness differences.

The production of poly tubes starts with the production of the basic material, polyethylene. Polymerization of ethylene from crude oil is required to manufacture polyethylene (PE). PE is a polymer that comes in various configurations ranging from low to high density, each with its own set of features and characteristics.

Extrusion, injection molding, blow molding, and rotomolding are the four most prevalent procedures used to manufacture poly tubes. Although all four processes entail heating the polyethylene material, each takes a different approach to shaping the tubing. How poly tubing is utilized is determined by the method used to make it.

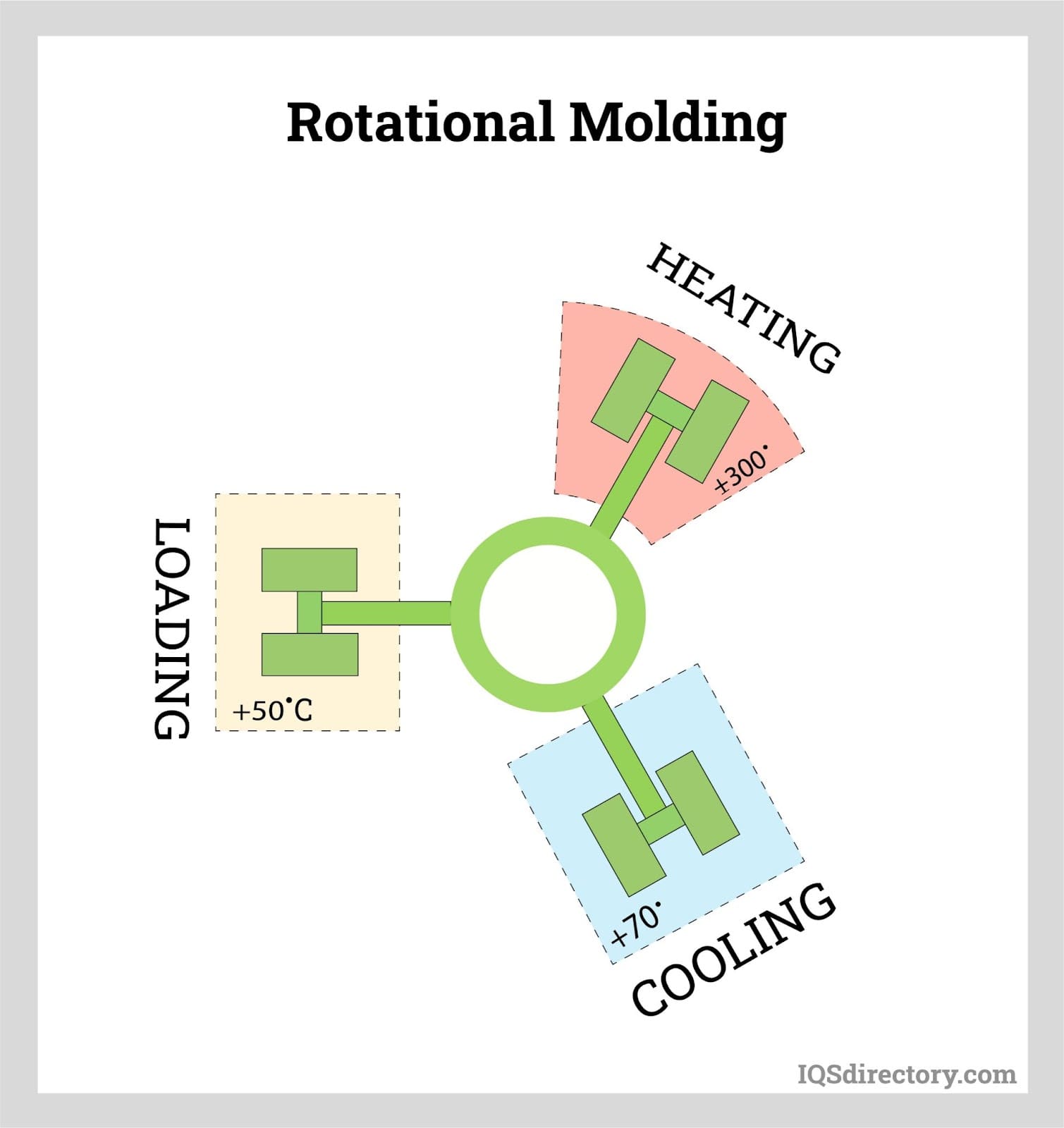

Rotational Molding Process

In rotational molding, powdered, granular, or liquid plastic is deposited in a mold and heated. The plastic powder melts and adheres to the sides of the mold as the mold is heated and rotated. The rotational molding procedure is used to create enormous poly tubes with complicated and complex designs.

The accuracy in creating poly tubes at just the appropriate thickness is the fundamental reason for adopting rotational molding. After the shape is produced, it is cooled, much like with extrusion. Rotational molding is cooled at room temperature, with a mist spray, or with a mixture of spray and room temperature.

Pultrusion Process

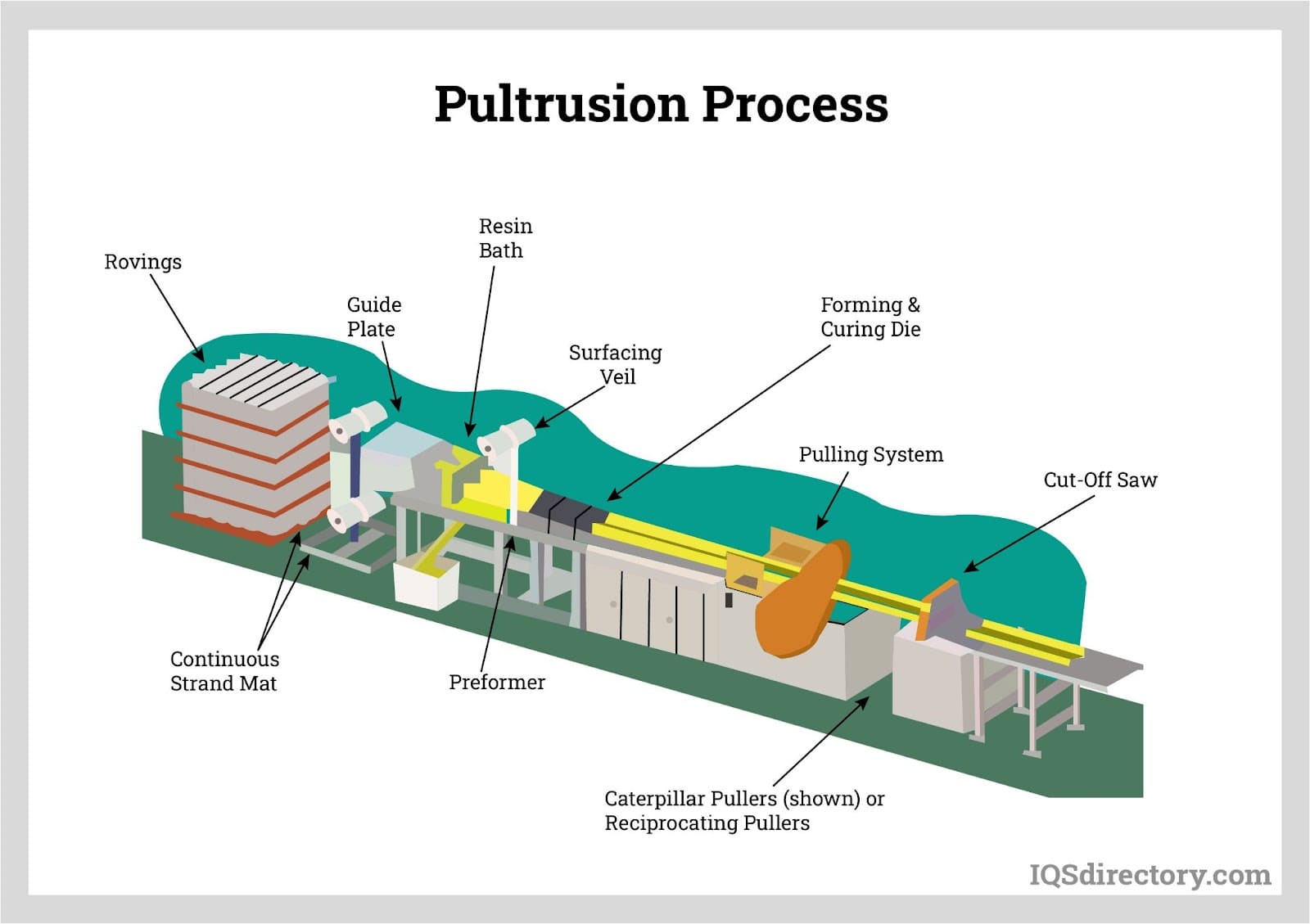

Pultrusion is a technique that involves tugging and extruding the material to be formed. Pultrusion, like extrusion, employs pressure to force molten material through a profile; however, pultrusion pulls the material through. The heated material is pulled through a die to make tubing. It passes over a mandrel as it is dragged through, which helps the formed material maintain its shape during the curing process.

Pultrusion allows for the production of a wide range of lengths and thicknesses. After the curing process, the continuous, unidirectional lengths are cut to size. Pullbraiding is an offshoot of pultrusion in which the fibers are braided together while the tubing is still hot when dragged through.

Changing the braiding process allows for the creation of layers with varied angles. Pultrusion and pull braiding produce extremely stiff tubing with a high strength-to-weight ratio. Pullbraiding has the benefit over pultrusion in that it creates balanced tubing that can handle a wide variety of loads and has a distinct appearance.

Applications of Poly Tubing

Medical Field

Tubing used for medicinal purposes is subject to stringent regulations. It must meet the specifications and regulations for medical and pharmaceutical applications, as well as manage a variety of medicinal fluids without causing damage or contamination. Tubing for anesthesia and breathing apparatus, intravenous tubes, catheters, and peristaltic pumps are all examples of medical poly tubing. When poly tubing is sold as medical tubing, it is clearly labeled with a list of the standards it meets and the uses it is suitable for.

Food and Beverage

Components used in the food and beverage sector must be created to ensure consumer sanitation and safety. To be accepted for food processing, the tubing must meet the FDA's legal criteria, which govern any product that comes into contact with food.

Choosing the Right Poly Tubing Manufacturer

To ensure you have the most productive outcome when purchasing poly tubing from a poly tubing manufacturer, it is important to compare several companies using our directory of poly tubing manufacturers. Each poly tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each poly tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple poly tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services