Poly tubing, also known as PE tubing or polyethylene tubing, is a lightweight, corrosion-resistant material that can be used for a variety of liquid, gas, and fluid transmission applications. PE tubing is made from polymers that give improved dimensional stability, homogeneity, and long-term strength. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

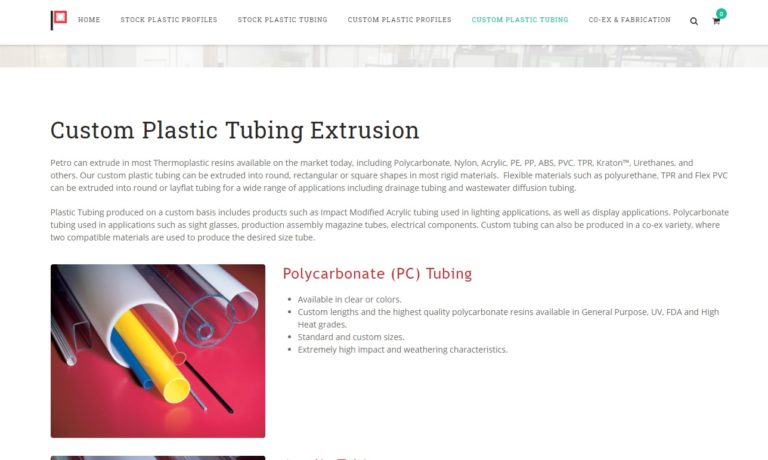

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Polyethylene Tubing Manufacturers

What is Polyethylene Tubing?

PE tubing is the most cost-effective option for chemical and food applications, as well as stress crack resistance. Additionally, laboratory-grade, FDA, NSF-51, and NSF-61 compliant, flame resistant for pneumatic controls in HVAC applications, and UV resistant for usage in sunny locations are all available options.

How Polyethylene Tubing is Made

The main method used in making polyethylene tubing is the extrusion process:

Extrusion Process

Like all other thermoplastics, polyethylene can be formed using various thermoforming techniques. However, plastic extrusion is the most frequent way of producing plastic tubes. Plastic extrusion is the process of melting raw plastic ingredients, forcing them through a die, and transforming them into usable plastic products.

The extrusion process starts with stock (raw plastic material) being collected in a hopper hung above a conveying channel. Next, the stock is guided into the conveyance channel, where it is pressurized and moved as it turns by a long, spinning screw. The twisting of the screw generates friction, which warms the stock as it moves through the channel.

The friction and heat from electric heating sources throughout the channel cause the stock to melt by the time it reaches the die. The die, a tool for shaping raw materials, is a large plate with a hole and pin in the case of plastic tubing. Molten stock is driven through the hole and emerges on the other side of the die as a newly extruded plastic tube.

The new tube is allowed to cool and harden once it has been formed. After that, it's cut to length and ready for shipment or further processing.

Types of Polyethylene Tubing

Polyethylene is a versatile plastic that can manufacture thin, break-resistant tubing or thick, break-resistant tubing with walls as thin as soda bottles. It has a variety of applications, including soda machines, municipal water systems, drainage systems, petrochemical processes, and many more. Polyethylene tubing is utilized for a wide range of purposes, which necessitates a large range of polyethylene variations.

Liquiflex POE Tubing

Liquiflex combines chemical resistance comparable to polyethylene, flexibility comparable to polyurethane, and great memory in a single tube. In addition, Liquiflex, like polyurethane and nylon, can be produced into self-storing, retractable coils. Liquiflex POE tubing is made of the same polymer family as polyethylene and polypropylene. It is suited for fluid handling, low-pressure applications, and other applications where users want flexibility and FDA compliance.

Linear Low Density Polyethylene Tubing

Compared to standard polyethylene tubing, linear low density polyethylene (LLDPE) tubing offers greater flexibility, tensile strength, and conformability. It's noted for its puncture and environmental stress crack resistance (ESCR). Gasses and moisture cannot pass through the LLDPE tube.

HDPE Tubing

The thickness, strength, and durability of high-density polyethylene make it ideal for transporting large volumes of liquids or pressured gasses. In addition, it is impact resistant and can withstand rusting.

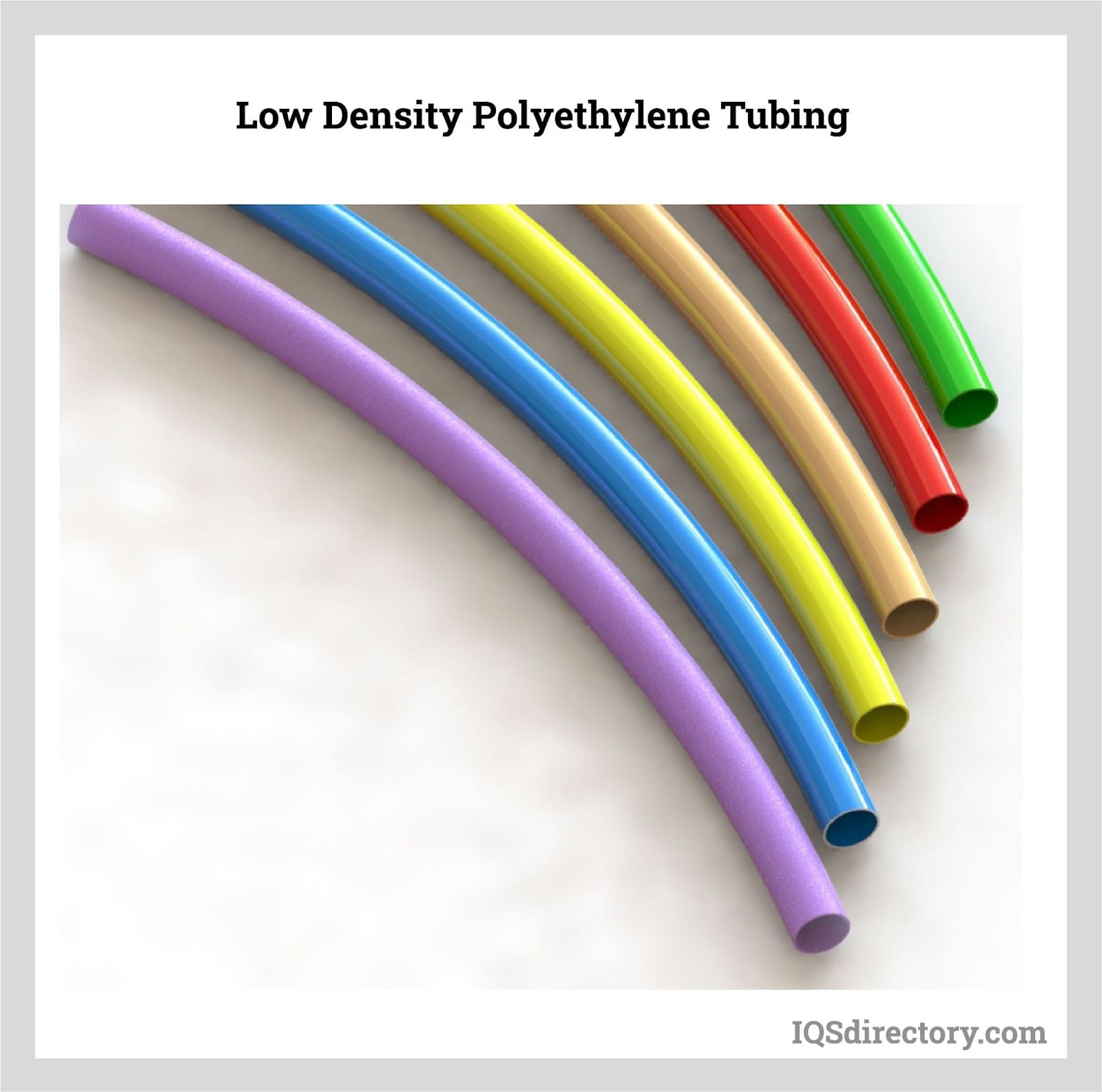

LDPE Tubing

The flexibility of low-density polyethylene contrasts with the rigidity of high-density polyethylene. LDPE is better for applications where the tubing is moved often or is attached to mobile equipment.

Applications of Polyethylene Tubing

Agriculture

Poly tubing or pipes are used in agriculture to irrigate crops because they do not corrode, rust, or decay. Irrigation canal fluctuations are a persistent challenge since they do not offer a constant volume of water. All that is required with poly tubing is to open the outlet. Water is continuously delivered without the need for maintenance or monitoring. Although poly tubing or piping has a higher initial cost, it is offset by cheaper labor expenses because it only requires two personnel to install. Poly tubing's dependability is another economic benefit, as it stays in place and does not shift or break. Poly tubing is available in several diameters and wall thicknesses to fulfill the needs of the irrigation project.

Air Compressors

Poly tubes are the preferred way of conveying compressed air in air compressors since they are highly reliable and efficient.

To be effective, air compressor tubing must deliver sufficient volume, quality, and pressure to power the component or device to which it is connected. Inappropriate tube design and connections result in higher costs and equipment damage.

Air compressor tubing is made of polyethylene, which does not corrode or rust and is lightweight and simple to connect and install. Its smooth inside allows air to flow freely, and its strength, toughness, and durability assure its long life.

Choosing the Right Polyethylene Tubing Supplier

To ensure you have the most constructive outcome when purchasing polyethylene tubing from a polyethylene tubing supplier, it is important to compare several companies using our directory of polyethylene tubing suppliers. Each polyethylene tubing supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each polyethylene tubing business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polyethylene tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services