Teleflex Medical OEM

Teleflex Medical OEMRequest A Quote

Gurnee, IL | 800-474-0178https://www.teleflexmedicaloem.com/

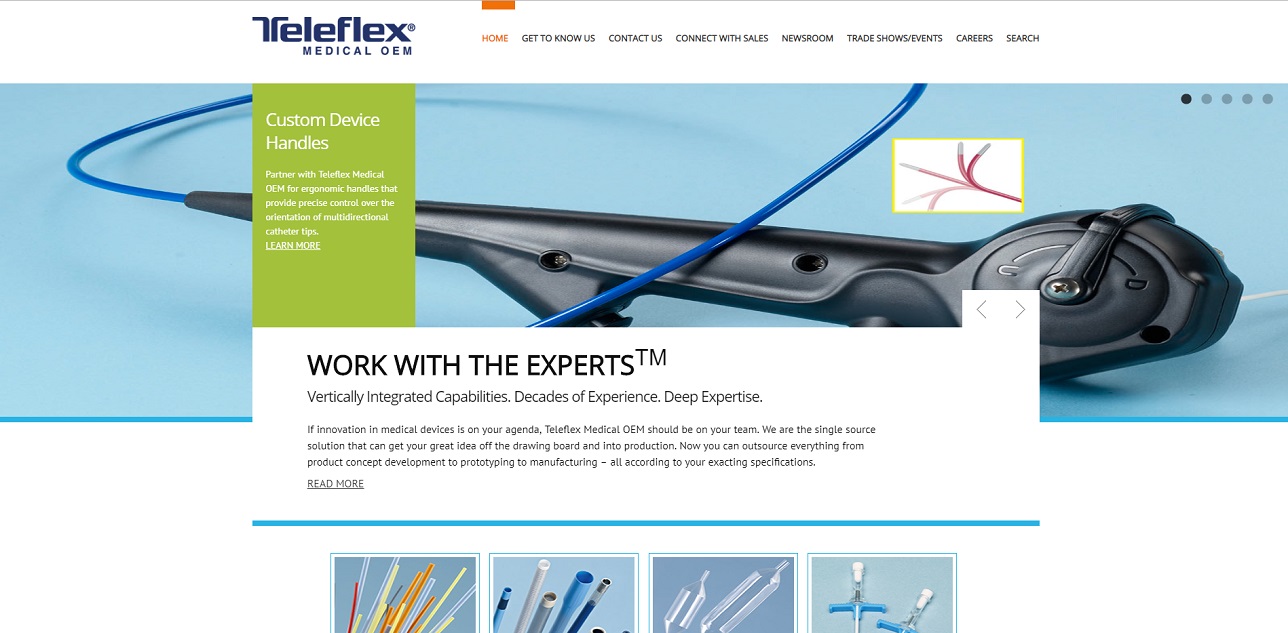

Teleflex Medical OEM is a leading provider of advanced medical solutions specializing in the healthcare industry. With a strong focus on plastic tubing, we deliver high-quality solutions that meet the diverse needs of medical device manufacturers worldwide. As trusted partners to the medical community, we leverage our extensive knowledge and experience to deliver customized plastic tubing solutions that are crucial in various medical applications. Our commitment to innovation, quality, and customer satisfaction has earned us a reputation as preferred suppliers and reliable partners in the medical OEM market. Our engineering expertise enables us to work with a wide variety of plastic materials, including polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polyurethane (PU), and other specialized polymers. In addition to our technical capabilities, we prioritize quality and compliance throughout our operations. We adhere to stringent quality management systems, including ISO 13485 and FDA regulations, ensuring that our plastic tubing products meet the highest safety, performance, and traceability standards. Teleflex offers comprehensive post-sales support, including ongoing product maintenance, technical assistance, and supply chain management. We understand the importance of agility and responsiveness in the dynamic medical industry, and we work closely with our clients to ensure timely delivery and seamless integration of our plastic tubing solutions. At Teleflex Medical OEM, we are a leading provider of advanced plastic tubing solutions for the medical OEM market. With a commitment to innovation and customer satisfaction, Teleflex delivers customized products that meet the unique needs of medical device manufacturers. Our expertise in plastic tubing, combined with our end-to-end capabilities, positions us as a trusted partner in the healthcare industry, driving innovation and improving patient care.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services